Pharmaceutical Liquid Filling Machine

- Pharmaceutical liquid filling machines expedite the manufacturing of liquid drug suspensions. Used by small and large drug manufacturing firms, liquid filling machines are designed in a variety of formats, from bench top sizes to larger scale models. Liquid filling equipment accommodates a range of liquid viscosities. Purchasing considerations for liquid filling equipment include the type of liquid to be packaged, handling considerations, required throughput, and the operation’s manufacturing and maintenance budget.

- Our Pharmaceutical Liquid liquid filling machines are designed to meet the changing needs of the Pharmaceutical Liquid industry. We manufacture the ideal machinery to handle your Pharmaceutical Liquid filling needs and meet your production goals.

The Roles of Pharmaceutical Filling Equipment

- Expediting small and large scale manufacturing

- Controlling for sterility and precise volumetric dispensing

- Facilitating continuous operation to meet output demands

- Providing automated or semi-automated control to the manufacturing process

Pharmaceutical Liquid Filling Machine Introduction

- Pharmaceutical industry is growing at a rapid rate with frequent new research and developments. It is considered as one of the prime industries for any developed or developing country that fulfils the basic and advanced health and medication services. Latest development and research work in medical science have generated the needs of advanced machinery for bulk drug production, processing and packaging. These machinery developments at low cost are quite efficiently possible in the developing country like India due to high resoruces, cheap labours and readily available raw materials. And these are the reasons that pharmaceutical Filling machine development industry is growing in India that is catering the world class Pharma machinery products at best pricing and packaging machineries across the globe countries.

- Filling line machineries are one the prime Pharma machineries for better production of liquid health chemicals for life’s benefit. Pharmaceutical machine manufacturing companies providing the wide range of packaging machineries like liquid filling machine, powder filling machines, capping machine, labelling machines, inspection machines, turn tables, tablet machines, blister packaging machineries, tablet press and tube filling machines. The ranges of machine models are high based on the variety of products packaging capacity. Here are few of the machines described for the functions related to them.

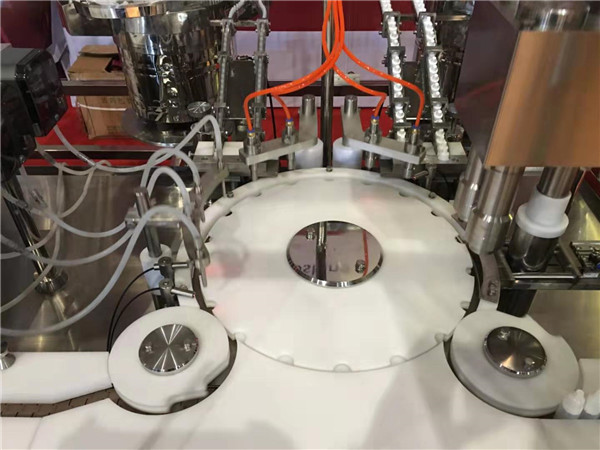

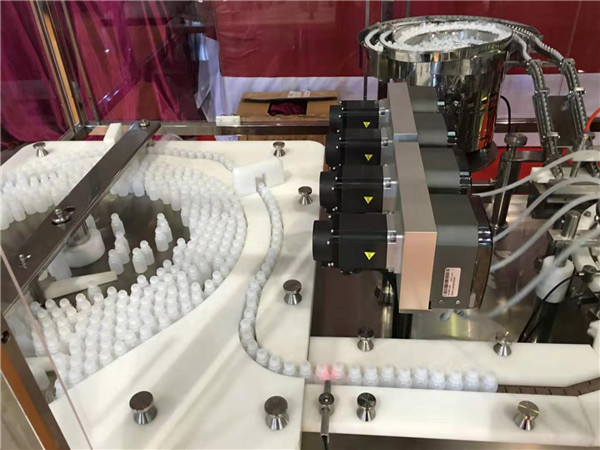

- Twin head liquid filling with rubber stoppering machine is a useful Pharma machine with two filling heads to fill the vials and automatic rubber capping after finishing the filling job. This machine is widely used in Pharma business for filling and capping vials. The same way this liquid filling is available in four head, six head and eight head filling capacity. The machine model with only filling feature without rubber stoppering is also available in low cost machine sections. These machines are mostly automatic for washing, cleaning of containers with washing machine, sliding of the bottles/vials, filling, capping etc are automized process in advanced machinery, though few are the models are provided with semi-automatic features by machinery manufacturing companies to reduce the machine cost.

- There are various types and kinds of filling machinery priced based on the capacity, features, functions, size and shape of containers to be filled etc. A single machine can be used as a multi-tasking machine as well you can integrate more than one Pharma machines to perform the task simultaneous. The costing of machines is completely depends on the machine capacity and features provided for process and packaging. Capping and labelling machines are also available in various models as the capping of bottles, vials, ampoules and any other size and shape of container is now amazing easy with flawless accurate filling measures.

Technical Parameters

| Description | Pharmaceutical Liquid Filling Machine |

| Output / Min | 40/60 Vials (Depending on the nature the liquid and its fill size or volume) |

| Power Characteristics | 440v 3 Phase 50Hz 4 Wire System |

| Fill Volume | 0.1 ml to 50ml |

| Filling Accuracy | ±1 % on Single Dose |

| Cap Dia | 20mm, 25mm 28mm |

| Net Weight | 550 kgs |

| Machine Length | 900mm |

| Machine width | 900mm |

| Machine height | 1400mm |

Flexible

- Exceptional flexibility adapts to small bottles

- E-cigarette fluids, eye drops and penicillin products

- Conveyor has adjustable guide rails and replaceable star wheels to suit different product configurations

Efficient

- Low energy consumption, high throughput

- Integrated touch-screen controls for ease of use and high productivity

- Volume Set feature to control all pistons through Servo System

- Volume for each piston can be set with one touch on screen – no manual adjustment required

Practical

- Management setting with password protection to restrict access

- Fully enclosed, easy to manage quick changeovers

- Built in mobility castors to make efficient use of floorspace