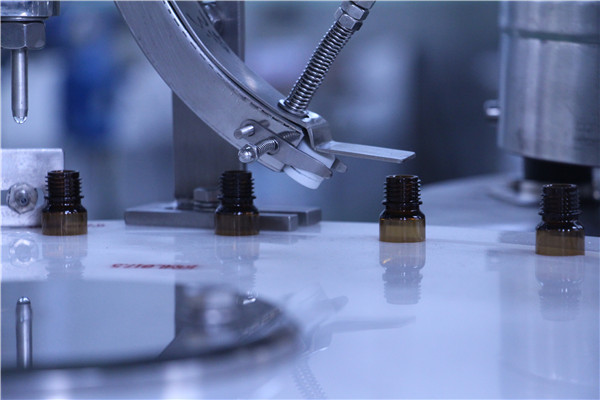

Fully Automatic Vial Filling Capping Machine

- Complete line (Vial Filling Machine) carefully design and developed as per New Pharmaceuticals Guide line and GMp Norms along with Modest Electronic Device programming and automation with timely service support.

- Automatic Six head Vial Filling Rubber Stoppering Machine.

Automatic Vial Filling Capping Machine Description

- Automatic Vial Filling Capping Machine suitable for e-cigarette liquids, penicillin products and eye drop products.

- IC Filling Systems filling / inserting / capping monoblock machine with unscrambler is suitable for low to medium viscosity liquids, with accurate peristaltic and piston pumps filling performance. This machine features double pumps/nozzles to achieve a high production speed. Fill more, faster.

- Its user-friendly design gives operators ease of operation, and is low maintenance for more uptime. You can choose between 2 or 4 pumps/nozzles to be fitted on your machine.

- The Nib and Caps feed through vibrating bowls, and the capping mechanism uses a Permanent Magnet Hysterisis Clutch and Brake to easily control the capping torque. Contact parts are made from high quality 316 stainless steel.

- Accurate bottle placements is assured by a servo-controlled star wheel to ensure perfect posiitioning for filling inserting and capping.

Simple to use, made for your needs...

- The monoblock’s highly efficient design allows easy operation and quick changeover for different product specifications. Each machine is designed and built to suit your specific requirements.

Technical Parameters

| Production capacity | 30-40 bottles/minute |

| Filling nozzle | 2 nozzles |

| Filling accuracy | ±1% |

| Press capping nozzles | 1 nozzles |

| Capping rate | 99% or more (depending on the characteristics of plug appropriate adjustment) |

| Speed control | frequency control |

| Bottle size | More than 10 mm |

| The power supply | 380 V 50 Hz |

| Power | 2 kw |

| Air supply | 0.3~04kfg/cm2 |

| Gas consumption | 10~15m3/h |

| Overall dimensions | 3000×1300×1700 mm |

Flexible

- Exceptional flexibility adapts to small bottles

- E-cigarette fluids, eye drops and penicillin products

- Conveyor has adjustable guide rails and replaceable star wheels to suit different product configurations

Efficient

- Low energy consumption, high throughput

- Integrated touch-screen controls for ease of use and high productivity

- Volume Set feature to control all pistons through Servo System

- Volume for each piston can be set with one touch on screen – no manual adjustment required

Practical

- Management setting with password protection to restrict access

- Fully enclosed, easy to manage quick changeovers

- Built in mobility castors to make efficient use of floorspace