Eye Drop Filling Machine

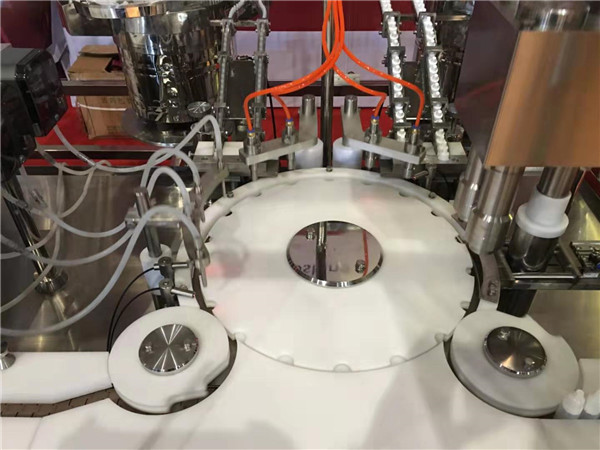

- The machine consists of one Side turntables, S.S. slat conveyor belt, eccentric pre-gassing, filling & post–gassing S.S. -316 nozzles precision-built S.S. – 316 Syringes, silicon rubber tubings, pneumatic system for inner cap placement, mechanical orientation type bowl & chute for outer cap placement, easy – reach compact panel etc. Due to its minimum distance between filling and stoppering, the risk of contamination is reduced. It is designed for operating in a sterile area and for utilizing it under laminar flow protection. The un-scrambler itself has been designed in the machine to eliminate dead ends and difficult to clean spot.

View Video

Eye Drop Filling Machine Description

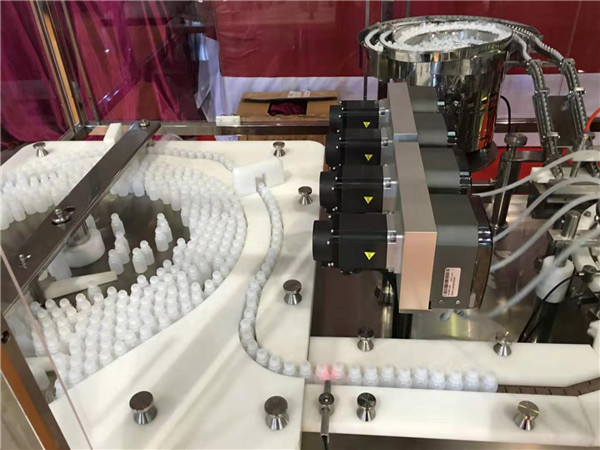

- The basic function of to fill the bottle plugging & screw capping ,Containers moving on SS Slat conveyor, feed towards the Star wheel which works on the principle of indexing mechanism which rotate clock wise the container entered into star wheel pocket which is the transferred by the star wheel toward filling station where diving type filling nozzle is mounted where the bottle is to be filled The filled container rotate and carry the bottle towards nozzle placing station where oriented nozzle is come in chute by vibratory feeder which pick by vacuum pickup system is spick and rotate 180 and place on bottle after this operation is to be transfer by star wheel to next station where oriented cap is to be come in chute which pickup by vacuum type pick up system is to be picked up by head and place on bottle after this operation is to be transfer for screw capping system where is to be cap is tighten by screw capping as desired torque once it finished the bottle is to be transferred toward exit conveyor for next operation

View Video

Feature

- Filling, Inner Cap Placement & Screw Capping Unit is completely in corporate in single body Structure.

- Pneumatic System for Inner Cap Placement

- Mechanical Orientation type Bowl & Chute for Screw Cap Placement

- All Liquid Contact Parts are of S.S. 316, the Body Structure is built up of S.S. 304 Pipe.

- Co-eccentric Nozzles allows very quick and precise setting and making unit compact and manageable.

- No vial, No Cap – Machine Stop System.

- Easy reach compact panel provides ease and operation

- Minimum Change over Time. From one size of container or fill size to another.

- Each Important individual part required for autoclaving/ sterilization can be removed easily.

View Video

Technical Parameters

| Description | Eye Drop Filling Machine |

| Output / Min | 40/60 Vials (Depending on the nature the liquid and its fill size or volume) |

| Power Characteristics | 440v 3 Phase 50Hz 4 Wire System |

| Fill Volume | 0.1 ml to 50ml |

| Filling Accuracy | ±1 % on Single Dose |

| Cap Dia | 20mm, 25mm 28mm |

| Net Weight | 550 kgs |

| Machine Length | 900mm |

| Machine width | 900mm |

| Machine height | 1400mm |

View Video

Flexible

- Exceptional flexibility adapts to small bottles

- E-cigarette fluids, eye drops and penicillin products

- Conveyor has adjustable guide rails and replaceable star wheels to suit different product configurations

View Video

Efficient

- Low energy consumption, high throughput

- Integrated touch-screen controls for ease of use and high productivity

- Volume Set feature to control all pistons through Servo System

- Volume for each piston can be set with one touch on screen – no manual adjustment required

View Video

Practical

- Management setting with password protection to restrict access

- Fully enclosed, easy to manage quick changeovers

- Built in mobility castors to make efficient use of floorspace