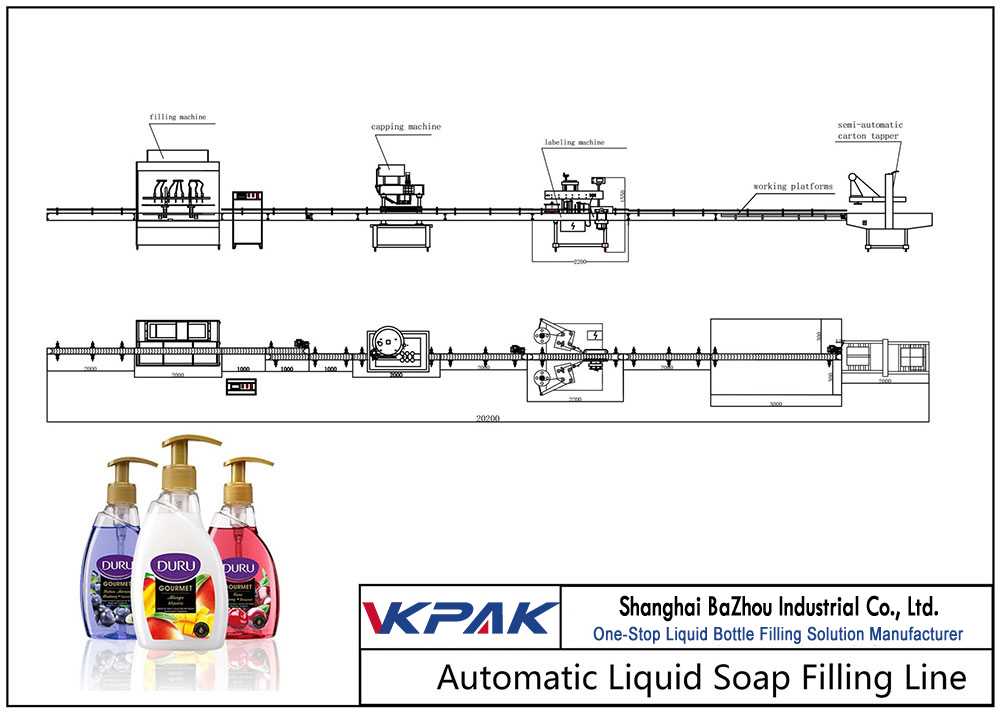

Automatic Liquid Soap Filling Line

- This automatic liquid soap filling line comes with everything you need to get your liquid soap bottling line up and running. It is designed to bottle 40-50 bottles per minute depending on product viscosity. Start your project today by filling out the form below!

- Main Composition:

- Automatic Liquid Soap Filling machine is controlled by computer via an auxiliary device (such as a cylinder block bottle system, stop bottles system, lifting system, feeding control, counting devices, etc.) to complete the automatic filling in the absence of personal operating conditions.

- Machines Main Included:

- Bottle Feeding Turntable

- Automatic 8 Head Servo Filling Machine

- Automatic Linear Capping Machine

- Automatic Bottle Labeling Machine

- Bottle Working Table Rolling Type

- Automatic carton sealing machine

- Product Description:

- – Full Automatic glass Plastic Bottle detergent, liquid soap,shampoo filling capping labeling line equipment for factory use

- – The machine design and reasonable, with beautiful and nice out look.

- – Adopts famous international electric components.Main power cylinder adopts Germany FESTO double function cylinder and electromagnetic switch. Japan MITUBISHI PLC microcomputer,OMRON photoelectric switch, Taiwan touch screen,ensure the outstanding quality and concestent stable function.

- – The machine if facilitate to maintain.not need any tool. It’s very easy to disassemble and install,cleaning.Adjustment volume could be large range to little range and then to fine adjustment.Could achieve no bottle or lack bottle not filling.High filling volume precision.

- -25-250ml,50-500ml,100-1000ml,250-2500ml ,The nozzles and the tank volume could be order according to the customers’ requirements. And the nozzles have 6,8,10 can be selected. The tank volume have four types, 25-250ml,50-500ml,100-1000ml,250-2500ml.With adjustable speed conveyor belt, and high strength stainless steel frame, firm and wear-used.

- – Considering the different visosities of the materials, specialize equipe with drip-proof filling chock plug and dive raising and declining system. In order to filling ain at the bottle ,design crosswise bayonet device, ensure position accurately.

- – The all filling system adopt clamp type facilitate install sanitary connections. The whole tank up and down could easy disassemble/clean and install without any tool. It’s structure is simple and easy to operate and maintain.