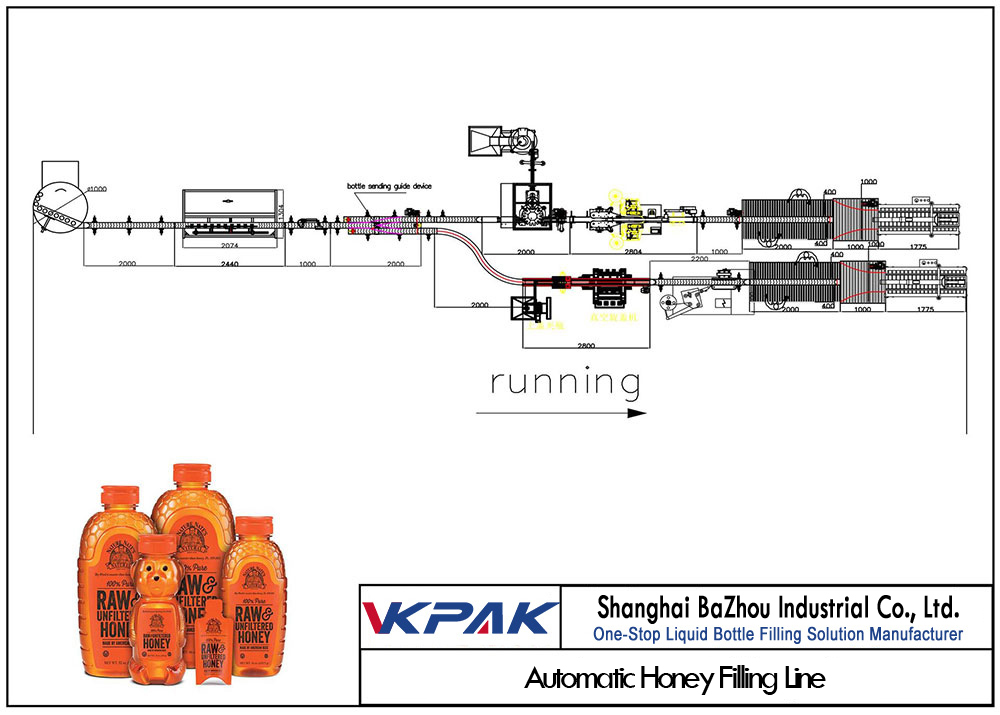

Automatic Honey Filling Line

- Honey Filling Line is manufactured by VKPAK for filling honey having the moisture content of up to 15%.

- This Filling Line is manufactured by us with very high-quality material and as per the defined industry standards to meet the changing needs of the Honey industry.

- The Honey Filling Machine comes in both automatic and semi-automatic versions.

- The output of the semi-automatic machine is app 8,000 – 10,000 bottles per day and the capacity for an automatic filling machine is 15,000 to 25,000 per day.

- Honey filling machine manufactured by us has been tested at various levels and it requires very low maintenance.

- As we have customized this machine as per client’s requirements, in compliance with various industrial standards it is user-friendly – very easy to operate, compact in design and it has long durability.

- We manufacture the ideal machinery to handle your Honey filling needs and meet your production goals.

- Machines Main Included:

- Bottle Feeding Turntable

- Automatic Servo Filling Machine

- Automatic Spindle Bottle Capper Machine

- Automatic Bottle Labeling Machine

- Bottle Working Table Rolling Type

- Automatic carton sealing machine

- Optional machinery:

- Bottle Cleaning Machine

- Disinfection equipment

- Read the technical specification and features of our most popular machine – Honey Filling Line.

- This honey bottle filling machine adopts piston pump to fill, suitable for all kinds of liquid, high precision; The structure of pump adopts shortcut dismantling organ, convenient to wash, sterilize.

- The piston ring of volumetric injection pump use different material of silicone, polyclonal or other kinds according to liquid characteristic, use ceramic pump in special industry.

- PLC control system, frequency conversion adjusting speed, high degree automation.

- No bottle, no filling, auto count the quantity. And have the anti-drop device.

- Filling quantity of all pumps is adjusted in a lump, minim adjustable for each pump. Easy and quick operate.

- Filling head is equipped with anti-dropping equipment, diving to the bottom to fill, rise slowly, to avoid bubble.

- The whole honey bottle filling machine is suitable bottles in different size, easy adjusting, and can be finished in short time.

- The whole honey bottle filling machine meets GMP requirement

- a) Products to Fill:

1) hot fill ( 35 ~ 40℃) , cold filling normal temperature

2) Specific Gravity: 1.1 ~1.4 gr/cm3

3) Spreading Chocolate past • Honey • Spreading Cheese paste, Molasses. - b) Bottle type:

1) PET bottle • Quadrant Cross section • Volume 250 ml. • neck 32 mm.

2) Glass Jars & PE, PET Jars • Cylindrical Cross section • Volume 200 ~ 350 ml.

• neck 45 mm. - c) Filling tolerances: +/- max 0.5%

honey Filling Machine basic composition

1.1 Bottles & Jars cleaning by air.

1.2 Automatic bottles feeding and holders (for plastic bottles if need)

1.3 No dripping.

1.4 Output 20 ~ 100 bpm.

1.5 No bottle No fill

1.3 Control panel with PLC touch screen. Malty filling programs saving.

1.4 Double jacketed Hopper with:

• 180 liters volume, • Level Detector. • Electric heaters.

• Product’s temperature detector and control • Stirrer

1.5 Easy dissembling the filling system and nozzles for cleaning.

1.6 Machine’s body of SS 304, all parts in contact with product is SSL 316.