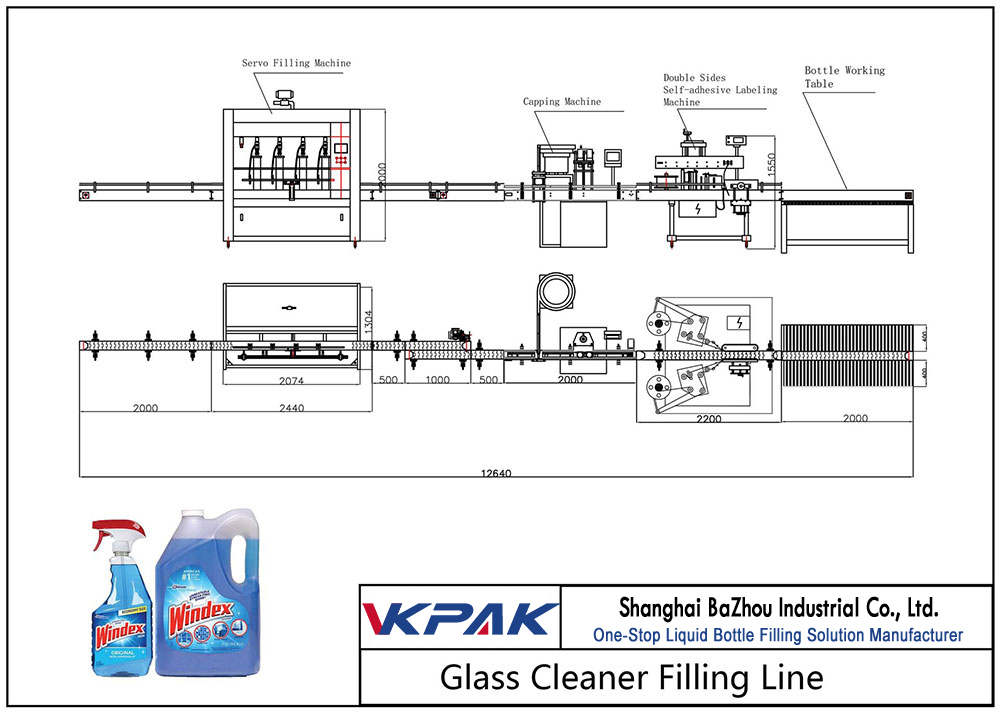

Automatic Glass Cleaner Filling Line

- Suitable for Floor Cleaner filling, capping, labeling and cartoning.

- Air Pressure: 0.4~0.6MPa

- Capacity: 2,000-5,000 BPH

- Filling Volume: 0~5L

- Required Operator: 3-4 workers

- Equipment Noise: ≤80dB

- This Automatic Glass Cleaner Filling Line comes with everything you need to get your liquid sweetener bottling line up and running. It is designed to bottle 30 bottles per minute. Start your project today by clicking request a quote below!

- Machines Main Included:

- Bottle Feeding Turntable

- Automatic Gravity Filling Machine

- Automatic Capping Machine

- Automatic Double Sides Self-adhesive Labeling Machine

- Bottle Working Table Rolling Type

- Automatic filling machine Have following features:

- Drip free nozzles with filling range of 50ml to 5000ml

- Non contact electronic sensor to ensure “no bottle no fill” system.

- Mitsubishi make plc system with 7” Touch screen and VFD control of C.G. make for conveyor speed control.

Gear Pump based filling machine with contact parts in stainless steel. - Body frame made up of stain less steel

- Capable of automatic intake of empty bottles / container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated.

- Fast flow and fine flow system for better accuracy, interval can be steed form PLC, Volume would be set individually for each nozzle with a increment of 1ml.

- Servo diving system for fomable products.

- 10 feet conveyor with 6 inches stainless steel slats and suitable for filling 50ml to 5 ltrs container along with electric motor for main drive and conveyor reduction gear box and variable frequency drive.

- Pneumatically operated stopper Gates for bottle entry and exit.

- Adjustment can be made without interrupting filling sequence.

- In built memory to store 25 filling setting data.

- Filling accuracy of +/- 0.25%

- 200 Ltrs stain less steel buffer tank with float valve.

- Enclosed Cabinet