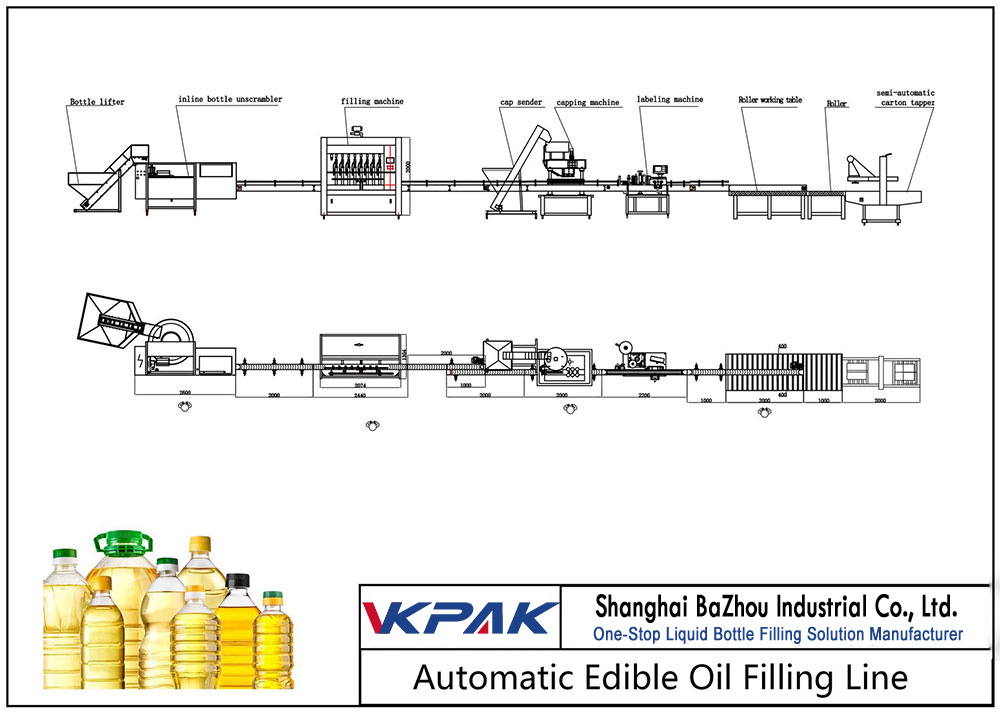

Automatic Edible Oil Filling Line

- As the name suggests, Automatic Edible Oil Filling Line is a setup of multiple machinery arranged in line and synchronization with one other so as to perform the ultimate function of edible oil filling. We are suppliers and exporters for the complete Edible Oil Filling Machines.

- Our range of Automatic Edible Oil Filling Machines comprises of Continuous Liquid Filling Machine as well as Servo Controlled Liquid Filling Machine. These machines are fabricated by our team of qualified engineers and technicians with the use of finest technology and components to bring out a superlative quality

- This automatic edible oil filling line comes with everything you need to get your edible oil bottling line up and running. It is designed to bottle 30-60 bottles per minute depending on product viscosity. Start your project today by filling out the form.

- Application:

- Our Oil filling machine suitable wide range oil like Peanut Oil , Sunflower Oil filler, Soybean Oil filling machine, Palm Oil filling machine, Coconut Oil filer , Cottonseed Oil filling machine, Mustard filling machine, Oil filler with capper machine, Corn Oil filling machine, Sesame Oil filling machine, Canola Oil filling machine, Shea Nut Oil filling machine and filling line including Bottle Unscramble, filler, capper ,Induction Cap sealer, Self adhesive Labeling machine, Sleeve labeling machine,carton packing machine

- Machines Main Included:

- Automatic Bottle Unscrambler

- Automatic Servo Filling Machine

- Automatic Linear Capping Machine

- Self-Adhesive Round Bottle Labeling Machine

- Description:

- PLC control, operation on touch screen

- Panasonic servo motor driven , automatic adjust the Filling size on HMI, eg. Users want to fill 500g oil, users just input the number 500, then the machine will automatic adjust

- It is volumetric by piston, high filling accuracy

- Easy adjustment, and tools free

- The soft tubes or pipes on the filler are adapt world brand Toyox from japan

- Specially made rotary valve for oil transfer

- O seals and Rings are specially chosen for oil

- Filling Machine Configuration List:

| Descriptions | Brand | Item | Remark |

| Servo motor | Panasonic | 1.5KW | Japan |

| Reducer | Fenghua | ATF1205-15 | Taiwan |

| Conveyor motor | ZhenYu | YZ2-8024 | China |

| Servo drivers | Panasonic | LXM23DU15M3X | Japan |

| PLC | Schneider | TM218DALCODR4PHN | France |

| Touch Screen | Schneider | HMZGXU3500 | France |

| Frequency Converter | Schneider | ATV12HO75M2 | France |

| Photo electricity of inspect bottle | OPTEX | BRF-N | Japan |

| Pneumatic Element | Airtac | Taiwan | |

| Rotary Valve | F07/F05 | No Need for Oil | |

| Pneumatic actuator | F07/F05 | No Need for Oil | |

| Low-Voltage Apparatus | Schneider | France | |

| Proximity switch | ROKO | SC1204-N | Taiwan |

| Bearing | China | ||

| Lead Screw | TBI | Taiwan | |

| Butterfly valve | CHZNA | China |

- Technical Parameters:

| illing Nozzles | 1-16Nozzles |

| Production Capacity | 800 -5000Bottles Per Hour |

| Filling Volume | 100-500ml,100ml to 1000ml, 1000ml to 5000ml |

| Power | 1500W to 3000W, 220VAC |

| Accuracy | ±0.1% |

| Driven | Panasonic Servo Motor |

| Inerface | Schneider Touch Screen |