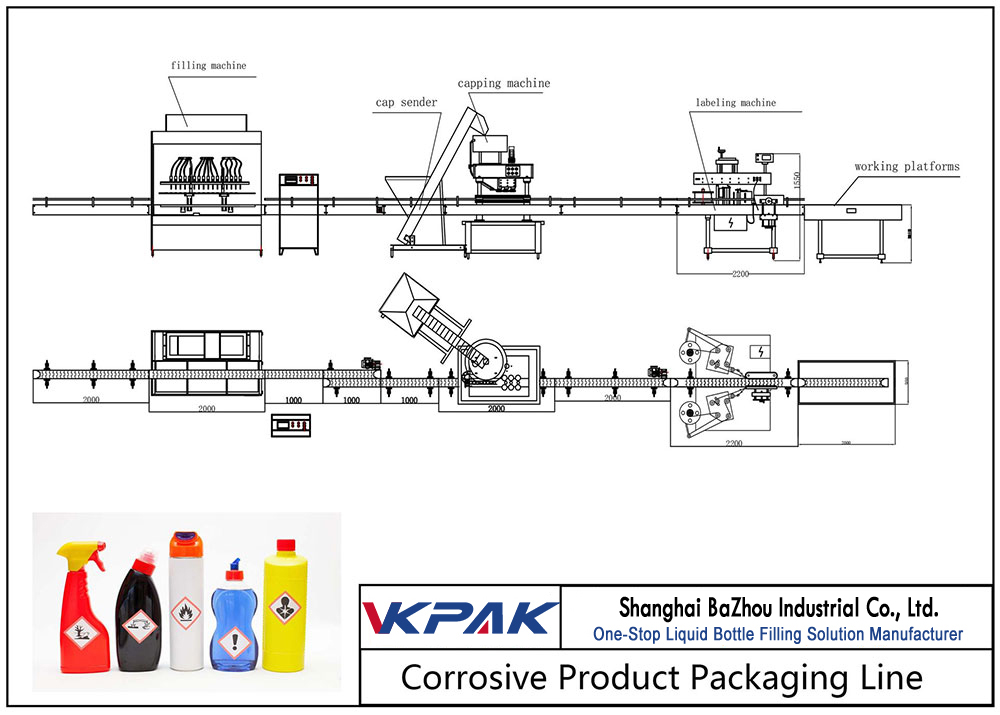

Automatic Corrosive Product Filling Line

- The VKPAK Automatic Corrosive Filler (ACF) is a specially designed timed flow volumetric filler for use in environments where caustic liquids and gasses cause accelerated deterioration to standard packaging machinery. The speed and ease of use make the ACF an ideal solution for chemical plants producing acids, bleach, ammonia, as well as food plants filling aggressive brine solutions. Each ACF machine is built from corrosive resistant material custom suited to the product they are intended for. They include a 10’ variable speed conveyor built from the same corrosive resistant components.

- Auto Corrosive Fillers also include a full digital color touch screen display with job memory, no bottle no fill, step fill or all fill modes, and total bottle counter with on the fly adjustability. ACF systems are easy to set up, operate, and adjust with minimal training. An optional all pnematic models is also available.

- Machines Main Included:

- Automatic Corrosive Liquid Filling Machine

- Automatic Capping Machine

- Automatic Labeling Machine

- Automatic Induction Sealing Machine

- Automatic Carton sealing machine

- Automatic Cartonning Machine

- VKPAK supplies a complete range of equipment to fill corrosive products to meet nearly any application. Made from HDPE (high density polyethylene, these filling machines, conveyors and turntables are designed to handle the punishment of a highly corrosive environment where standard metal components would normally dissolve.

- VKPAK poly filling systems use volumetric filling methods, which are extremely accurate and versatile. The fillers are designed to fill from a fraction of an ounce up to five gallons and are capable of handling viscosities ranging from thin and foamy to very thick liquids. VKPAK’s modular design can allow the design of the filler machines to have multiple tanks and fill head assemblies to isolate non-compatible products within a common frame. All VKPAK fillers are built to provide the best combination of maximum versatility, easy setup and changeover, and minimal down-time for maintenance and cleaning. VKPAK also manufactures this type of bottling equipment for table-top applications.

- Main performance and structure features:

- 1. Control system – with Mitsubishi PLC control system, filling dose of random tuning

- 2. Operation interface – colorful screen interface, human-machine interface is simple, safe and reliable

- 3. Feature Enhancements – Cutting with anti-drip device, it can dive to fill with materials. (This feature can be optional)

- 4. Electrical components – using internationally renowned brands to ensure the equipment is reliable and of high accuracy.

- 5. Mechanical components – the main parts is made of high quality PP frame, contact part is made of non-toxic corrosion silica gel, PTFE hoses, valve is PVC.

- 6. Extensions – can be customized for specific configuration requirements, such as: material sealed, heating, sterilization, etc..

- 7. Count testing – real-time count, reflecting on the work output directly.

- 8. Filling Detection – No bottle, or when bottle filling number is not enough, no filling

- Technical Parameters

| Applicable specifications | 100-5000ml |

| Production capacity | 1000-2500 bottles /hour(4/8/12/16 filling heads ) |

| Filling accuracy | ±1% |

| Capping rate | ≥99% |

| Power supply | 380V / 50Hz |

| Power | 2.5kW |

| Total dimension | 2500 * 900 * 2500MM |