Automatic Cleaning Chemical Filling Line

- Automatic liquid fillers are normally manufactured for companies with higher daily production demands.Though not every machine will be pushed to full capacity on every given day,The machinery is meant to make the filling process efficient and reliable.

- When companies are packaging more than one single product, changeover from one product to another can cut into production time. Even for companies with a single product, clean up at the end of the production day can mean precious filling time is lost. Changeover and clean up time can be shortened by using a clean in place system on an automatic filler.

- Filling machinery will arguably take the most time to clean or changeover due to the fact that the equipment handles the actual product being packaged. The product pathway and plumbing may require disassembly to properly cleanse the machine and avoid product build up, caking, contamination and other issues. In many cases, a clean in place system removes the need for such disassembly, reducing downtime significantly.

- A clean in place system for an automatic filling machine will generally flush the fluid pathway of the machine with a cleaning fluid or hot water, depending on the product and needs of the packager. A spray ball in the supply tank allows the tank to be cleaned and a supply pump, or a separate pump, will be used to move through the product pathway, piping and nozzles as well. The clean in place system can be set up to work through the product infeed system to flush and clean the supply line and will normally be controlled via the operator interface on the automatic filler, though separate CIP systems can also be integrated into the packaging line depending on the needs of the packager. A good clean in place system removes the need for the operator of the filling machine to do anything more than set up the cycles and times on the control panel.

- The operator interface of the PLC will include a separate screen for the control of the clean in place system. Reached from the main menu, the simple to use controls will allow the operator to set delay and duration times and then start the clean in place cycle or cycles with the push of a button. Again, the configuration and the actual controls may vary depending on the needs of the packager and the machine itself.

- Different configurations can be added to filling equipment for different needs or custom filling machinery. Even manual systems can be added to semi-automatic liquid fillers to speed up the cleaning process. The clean in place system is only one of the many attributes of an automatic filler that can save production time. Other features include a recipe screen on the operator interface to recall indexing times, fill times and other information to make set up quick and simple, hand knob adjustments for nozzles and rails, drip trays to contain excess product and other optional features. Our Packaging Specialists are always available to discuss your packaging machinery needs and help to identify the ideal solution for each individual project.

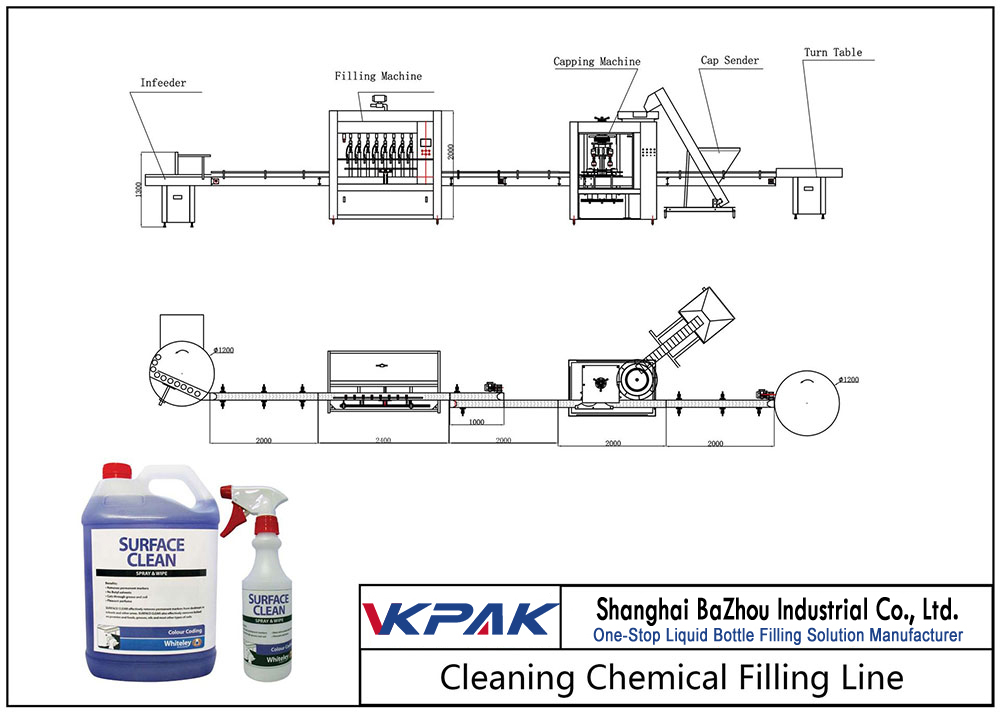

- Machines Main Included:

- Bottle Feeding Turntable

- Automatic Gravity Filling Machine

- Automatic Rotary Capping Machine

- Automatic Bottle Labeling Machine

- Bottle Working Table Rolling Type

- Automatic filling machine Have following features:

- Drip free nozzles with filling range of 50ml to 5000ml.

- Non contact electronic sensor to ensure “no bottle no fill” system.

- Mitsubishi make plc system with 7” Touch screen and VFD control of C.G. make for conveyor speed control.

- Gear Pump based filling machine with contact parts in stainless steel.

- Body frame made up of stain less steel

- Capable of automatic intake of empty bottles / container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated.

- Fast flow and fine flow system for better accuracy, interval can be steed form PLC, Volume would be set individually for each nozzle with a increment of 1ml.

- Servo diving system for fomable products.

- 10 feet conveyor with 6 inches stainless steel slats and suitable for filling 50ml to 5 ltrs container along with electric motor for main drive and conveyor reduction gear box and variable frequency drive.

- Pneumatically operated stopper Gates for bottle entry and exit.

- Adjustment can be made without interrupting filling sequence.

- In built memory to store 25 filling setting data.

- Filling accuracy of +/- 0.25%

- 200 Ltrs stain less steel buffer tank with float valve.

- Enclosed Cabinet

- 1. Installation, debug

After equipment reached the workshop of customer, place the equipment according to plane layout we offered. We will arrange seasoned technician for equipment installation, debug and test production at the same time make the equipment reach the rated producing capacity of the line. The buyer need to supply the round tickets and accommodation of our engineer, and the salary. - 2. Training

Our company offer technology training to customer. The content of training is structure and maintenance of equipment, control and operation of equipment. Seasoned technician will guide and establish training outline. After training, the technician of buyer could master the operation and maintenance, could adjust the process and treat different failures. - 3. Quality guarantee

We promise that our goods are all new and not used. They’re made of suitable material, adopt new design. The quality, specification and function all meet the demand of contract. We promise that the products of this line could storage for one year without adding any aseptic. - 4. After sales

After checking, we offer 12 months as quality guarantee, free offer wearing parts and offer other parts at the lowest price. In quality guarantee, the technician of buyers should operate and maintain the equipment according to seller’s demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems. The cost of technician arrangement you could see the cost treatment method of technician. - After quality guarantee, we offer technology support and after sales service. Offer wearing parts and other spare parts at favorable price; after quality guarantee, the technician of buyers should operate and maintain the equipment according to seller’s demand, debug some failures. If you could not solve the problems, we will guide you by phone; if the problems are still can not solve, we will arrange technician to your factory solving the problems.