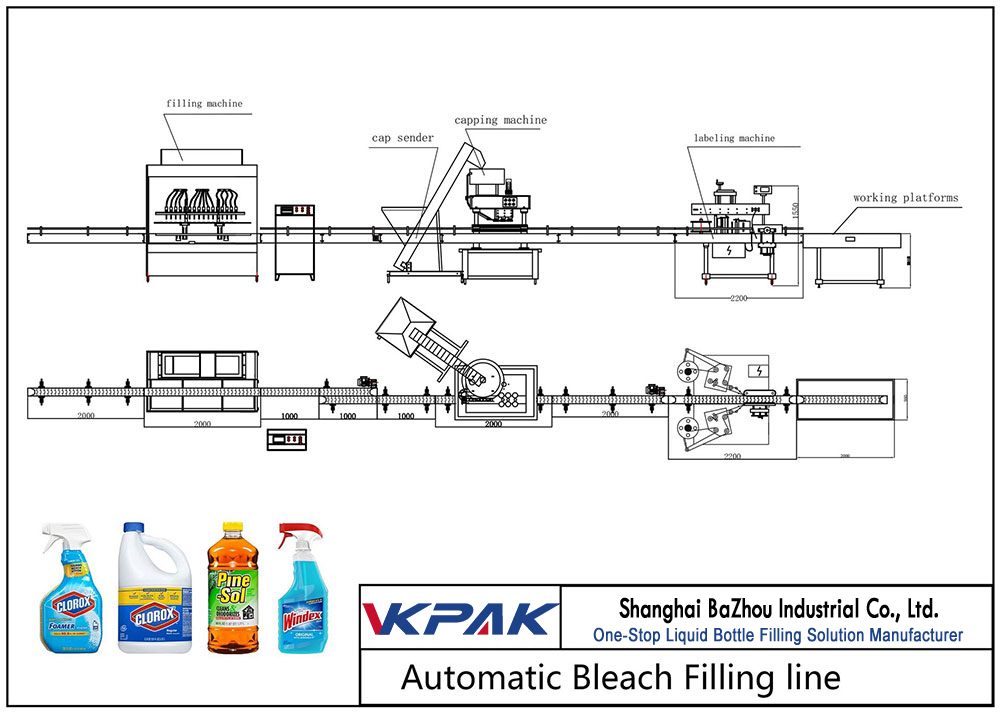

Automatic Bleach Filling Line

- We recommend you our automatic oblique neck bottle Piston/Gravity filling machine. (1) Multi filling nozzles, made of PP and Alloy, in anti-corrosive (2) Capacity, it can fill 500-3000 bottles each hour.

- Direction of fill nozzles is available for change to fill oblique neck bottles.

- Brief Introduction:

- <1 > Suitable material: Bleach, acid liquid, 84 disinfectant, gel water, toilet cleaner, especially used in the liquid filling of strongly corrosion liquid and cosmetics which can’t touch the metal.

- <2> Contact liquid parts are use anticorrosive non-metallic material and with diving function.

- <3 > This Vertical filler is a high-tech filling equipment integrating on the PLC microcomputer programmable control, and photo electricity transduction pneumatic action.

- <4 > The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes. Short filling circle, high production capacity.

- <5> User may choose the filling volume and decide the filling heads per own production capacity.

- <6 > The precision time of the pneumatic valve filling may set to 0.01 second, can make the measurement precision control within ±1%, to decrease unnecessary material loss and enhance the economic efficiency.

- <7 > Each filling-head’s measurement may be individually adjusted to realize the same filling measurement.

<8> The machine set such function: having counting program of bottle-feeding, doesn’t fill as there is not bottle or the counting doesn’t attain a predetermined position, can start filling only when the counter records that the bottle number is same as the setting filling number. - <9 > More or less of the filling volume, may initially adjust to the needed filling volume, then micro adjust, can get the ideal filling measurement precision.

- Machines Main Included:

- Bottle Feeding Turntable

- Automatic Anti-corrosive Gravity Filling Machine

- Automatic Capping Machine

- Automatic Double Sides Self-adhesive Labeling Machine

- Bottle Working Table Rolling Type

- Machine introduction: Automatic inline gravity/piston liquid filling machine is a newest version product made by our company. It is developed wholly in corrosion standard. It is a high-tech filling equipment which is a combination of microcomputer (PLC) controlled photoelectric sensor and pneumatic actuator. It is specially used for high corrosive liquid, such as bleach liquid, 84 disinfection liquid, HCL, Sulfuric acid liquid, toilet clean fluid, Bleach liquid ,and so on. And also has a function of Dive filling (Driving filling or not, depend on buyers.). With features, such as precise filling volume, no drip, photoelectric detection, no filling when without bottle.

- Piston/Gravity type HCL filling machine also have following advantages:

- (1) Three-way valves, we install them separately from filling and let them in isolated room in machine back.

(2) Such valves do not touch the corrosive liquid and not be damaged by corrosive air, too. - (3) Piston cylinders are set under the machine back, which are tailor-designed fro anti-corrosive. And Pistons have 2 sealing rings, which guarantee it 100% no leaking and dripping, but also guarantee that after use in several years, even the sealing rings damaged, it also run without leaking and dripping. The replace of sealing rings is easy and simple, too.

- (4) The piston cylinders we use are made of glasses and wrapped by PP material cover . Inner wall of this glass piston cylinder is very smooth and has very small resistance to sealing rings, more longer life and convenient.

- (5) Specially-designed drawing valve are made of F4 material.