Shampoo Filling Machine

- When you are bottling Shampoo there are several types of filling machines you may choose.

- Our Shampoo liquid filling machines are designed to meet the changing needs of the Shampoo industry. We manufacture the ideal machinery to handle your Shampoo filling needs and meet your production goals.

View Video

Shampoo Filling Machine Introduction

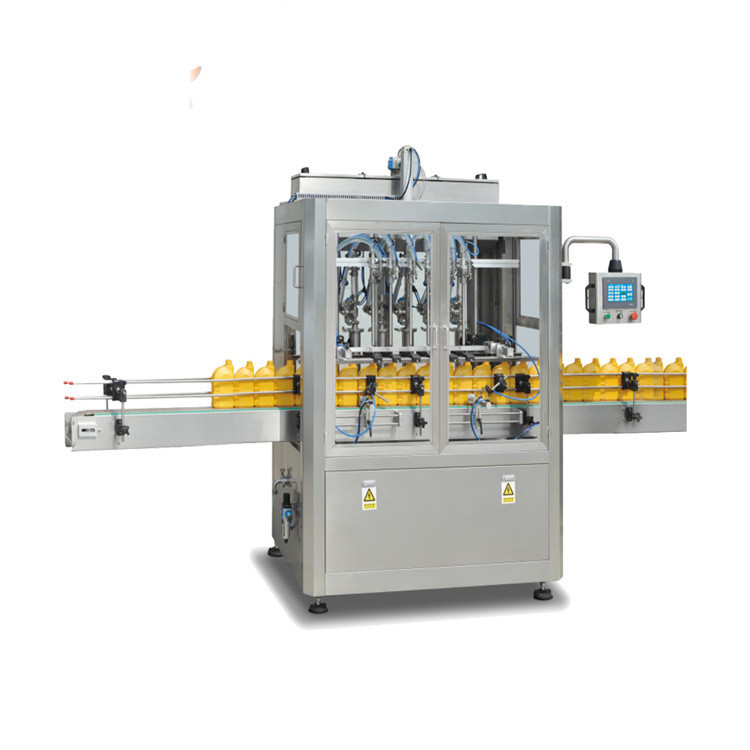

- Automatic Volumetric Shampoo bottle filling machine, which is made compact, versatile and enclosed in stainless steel elegantly matt finish body. This unit works on volumetric principal and reciprocating self-centring device.

- Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose.

- The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum of time.

- The main drive consists of a helical gearbox driven by A/c motor & through controlled by an Ac frequency drive. The speed can be set in terms of bottles per minute. The conveyor drive consists of a hallow shaft, geared motor controlled by an Ac frequency drive. A knob can set the speed of conveyor.

View Video

Shampoo Filling Machine Features

- 1.filling nozzles from 2 -16 nozzles for option

- 2.anti- drops, equipped with shut off filling nozzles

- 3.when filling, the filling nozzles will insert into the bottom of the bottles

- 4.Filling volume can be automatically adjusting by touch screen , meanwhile customer also can choose adjust by rotary handle for economy investment.

- 5.Frequency speed control, and no bottle no filling

- 6. Shampoo filling machine is designed to be compact and reasonable.

- 7. Choosing the international brand of electrical components. The main powered cylinder, chose the Taiwan Airtac double-action cylinder and magnetic switch, the Japanese Mitsubishi PLC computer, photo electricity and Taiwan-manufactured touching screen, ensuring a good quality and lasting steady performance.

- 8. Convenient maintenance without any tools. This machine can be dispart, cleaned and fixed easily.Filling precision and quantity are adjustable and should be regulated among a big range firstly,then be trimmed.

- 9. We can customize the filling machine with specific filling-head number and particular cylinder volume,based on the user’s production demand. 6-head, 8-head and 10-head can be chosen.The cylinder volume can be chosen from 25-250ml, 50-500ml, 100-1000ml and 250-2500ml. The whole machine is speed-adjustable.

- 10. Considering the different viscosity of user’s material ,we especially set a special filling valve to adjust to different situations. and We also designed a descending filling lift system. In order to make the material-falling accurate at the bottle mouth , we designed a horizontal bottle-aiming fixture device.

- 11. The machine set a weight filling program to fix the flow parameter and makes the machine adjustable to the complicated material varieties. The system can realize the one-machine multi-use without other parts and decrease the equipment’s repeated investment.

View Video

Advantage of Shampoo Filling Machine

The 50-1000ml shampoo packaging machine is suitable for low viscous liquid bottles containers that are less than 1000ml in volume. With an automatic bottle unscrambler, filling machine, rotary capping machine and gluing/self-adhesive labeling machine, the chemical packaging line is a complete production line that packages and seals cartons. This effective bottle packaging machine is adjustable to fill low viscous liquids such as cleaners, detergent,liquid soaps and other low viscous liquid and applies anti-theft caps.

- The unit is made compact & versatile.

- S.S. Slat conveyor.

- S.S. Elegantly Matt Finished Body.

- No Container No filling system.

- Reciprocating Filling nozzle with self centring device.

- Variable A/c Frequency Drive.

- Pneumatically operated bottle stopper.

View Video

Shampoo Filling Machine System

- Rinsing System

- Shampoo filling equipment applies unique overturning bottle clamp, which is hygienic and durable. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

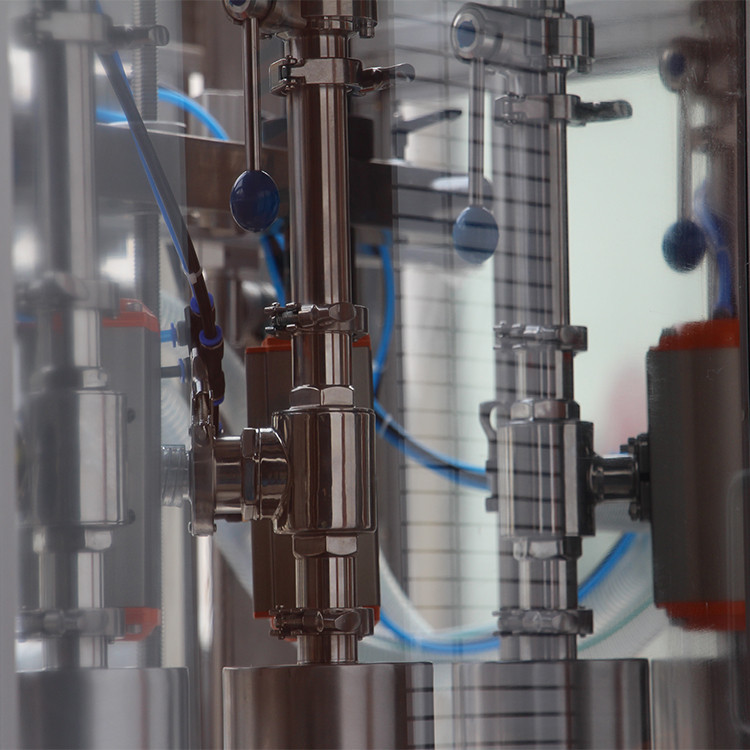

- Filling System

- Clip the bottle neck with steel starwheel. There is no need to adjust the equipment height when changing the bottle shape whose diameters have no much change.

- Rotating disks all make from stainless steel. Large planar toothed bearings can ensure the stable operation of machine.

- High-precision electronic liquid level filling valve makes fast and slow fillings possible.

- Automatic washing cup can circularly and thoroughly clean the filling valve through CIP cleaning program.

- Integrate filling valve with bottle lifting mechanism. The simplified structure makes cleaning easier and could improve the stability of the machine. Bottleneck is clipped by clippers.

View Video

Advanced design

- 1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

- 1.2 Short filling circle, high production capacity.

- 1.3 Changing filling circle, high production capacity.

- 1.4 User may choose the filling volume and decide the filling heads per own production capacity.

- 1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

- 1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

View Video

Shampoo Filling Machine Main performance parameters

| Brand | VKPAK |

| Model | VK-PF |

| Product to be Filled | Shampoo |

| Fill Volume | 10– 1000 ml as per requirements |

| Output/Min | Up to 30-200 depending on material foaming character |

| Direction of Movement | Left to Right |

| Number of head/syringe | 2 to 16 Nos. |

| Electrical Specification | 2.0 HP / 415 Volts / 50 Hz.(Main Machine) |

| 1.0 HP / 415 Volts / 50 Hz. (Conveyor) | |

| Height of Conveyor | 860 mm to 910 mm adjustable. |

| Net Weight | 600 Kgs. |

| Change parts required | (A) Syringes. (B) Nozzle (C) Inlet & outlet hose pipe |