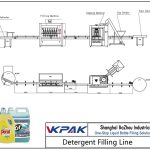

Detergent filling machine

- When you are bottling Laundry Detergent there are several types of filling machines you may choose

- Our Laundry Detergent liquid filling machines are designed to meet the changing needs of the Laundry Detergent industry. We manufacture the ideal machinery to handle your Laundry Detergent filling needs and meet your production goals. .

View Video

Detergent filling machine Introduction

- All the machine material are constructed by PVC to anti corrosive including the conveyor, control box.

- Schneider PLC control, and Schneider touch screen operation it is easy for changing size or modifying parameters.

- Pneumatic elements are all imported, stability and reliability.

- Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

- Close positioning design, easy governing, suitable for packing of all sizes of bottles.

View Video

Detergent filling machine Features

- Adopting the world-famous brands, like Japanese Omron light contaol elementand Japanese SMC pneumatic components, the automatic liquid detergent filling line has the incomparable advantages of low failure rate, stable and reliable performance as well as the surprising longevity. Also can be customized according to customs’ requirements.

- Speed control: frequency conversion adjusting speed

- The automatic liquid detergent filling line is designed according to GMP requirements, which is made of stainless steel under the internatioal of SUS316L, SUS304

- It adopts no bottle no filling system. Unique drip proof device in production process, ensure no irrigation constant filling function.

- The automatic liquid detergent filling line will alarm or stop workiing automatically if unconventional problems happen(such as counting mistake, miss bottles)

View Video

Advantage of Detergent filling machine

- Use strong and long life PVC material

- PLC control, and adjust the filling volume by touch screen

- Low cost for investment

- Diving filling head to anti foamy

View Video

Detergent filling machine System

- Rinsing System

- Detergent filling equipment applies unique overturning bottle clamp, which is hygienic and durable. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

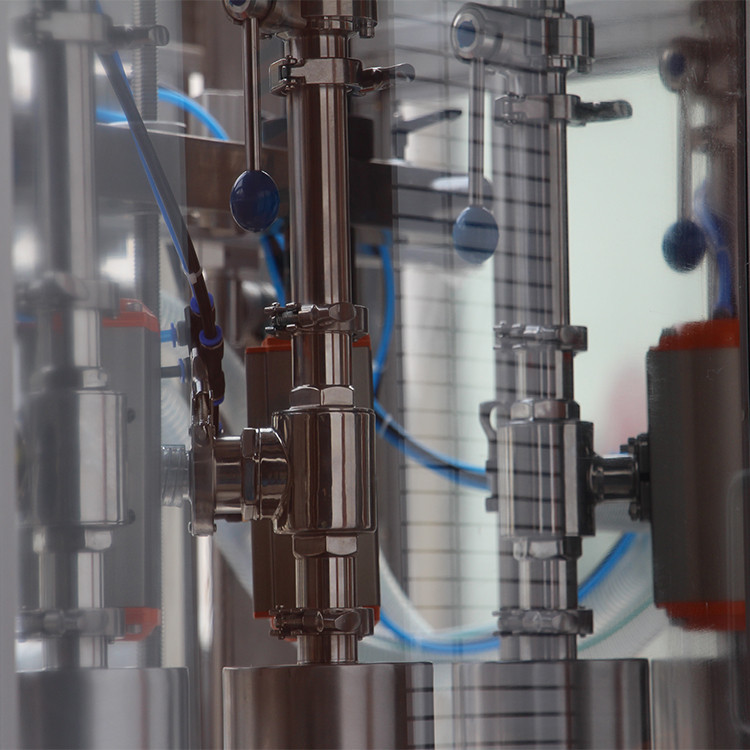

- Filling System

- Clip the bottle neck with steel starwheel. There is no need to adjust the equipment height when changing the bottle shape whose diameters have no much change.

- Rotating disks all make from stainless steel. Large planar toothed bearings can ensure the stable operation of machine.

- High-precision electronic liquid level filling valve makes fast and slow fillings possible.

- Automatic washing cup can circularly and thoroughly clean the filling valve through CIP cleaning program.

- Integrate filling valve with bottle lifting mechanism. The simplified structure makes cleaning easier and could improve the stability of the machine. Bottleneck is clipped by clippers.

View Video

Advanced design

- 1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

- 1.2 Short filling circle, high production capacity.

- 1.3 Changing filling circle, high production capacity.

- 1.4 User may choose the filling volume and decide the filling heads per own production capacity.

- 1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

- 1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

View Video

Specification

| Name | automatic liquid laundry detergent filling machine |

| Production capacity | 1000-6000 bottles/h |

| Filling capacity | 50-5000ml can be customized |

| Bottle size | 20-5000mm |

| Package accuracy | ±1% |

| Sealing rate | ≥99% |

| Air pressure | 0.4-0.6MPa |

| Material | stainless steel of 304 or 316 |

| Machine weight | 650kg |

| Power | 220v or 380v |

| Warranty | one year free |

| Certificate | ISO9001, CE, meet with GMP standard |