Automatic Liquid Soap Filling Machine

- When you are bottling Liquid Soap there are several types of filling machines you may choose.

- Liquid soap is one of the thicker liquids that require machinery that can effectively handle it. VKPAK Machinery carries a selection of liquid soap filling equipment and other packaging machinery that can complete orders with consistent efficiency and accuracy. We can help you select the best machinery to use in your facility based on your specific needs, completing your production line.

View Video

Liquid Soap Filling Machine Introduction

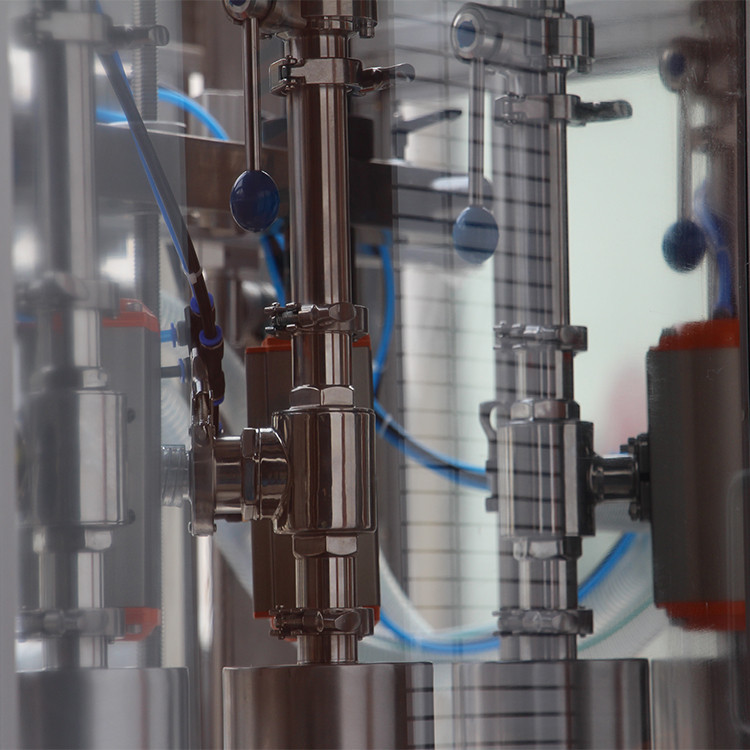

- Automatic Volumetric Shampoo bottle filling machine, which is made compact, versatile and enclosed in stainless steel elegantly matt finish body. This unit works on volumetric principal and reciprocating self-centring device.

- Nozzle goes upwards slowly from the bottom level of bottle towards neck during filling to minimize forming adjustable nozzle is reciprocating according to filling dose.

- The dosing block with a hexagonal bolt, this means different fill size can be set easily within minimum of time.

- The main drive consists of a helical gearbox driven by A/c motor & through controlled by an Ac frequency drive. The speed can be set in terms of bottles per minute. The conveyor drive consists of a hallow shaft, geared motor controlled by an Ac frequency drive. A knob can set the speed of conveyor.

View Video

Liquid Soap Filling Machine Features

- 1.filling nozzles from 2 -16 nozzles for option

- 2.anti- drops, equipped with shut off filling nozzles

- 3.when filling, the filling nozzles will insert into the bottom of the bottles

- 4.Filling volume can be automatically adjusting by touch screen , meanwhile customer also can choose adjust by rotary handle for economy investment.

- 5.Frequency speed control, and no bottle no filling

- 6. Shampoo filling machine is designed to be compact and reasonable.

- 7. Choosing the international brand of electrical components. The main powered cylinder, chose the Taiwan Airtac double-action cylinder and magnetic switch, the Japanese Mitsubishi PLC computer, photo electricity and Taiwan-manufactured touching screen, ensuring a good quality and lasting steady performance.

- 8. Convenient maintenance without any tools. This machine can be dispart, cleaned and fixed easily.Filling precision and quantity are adjustable and should be regulated among a big range firstly,then be trimmed.

- 9. We can customize the filling machine with specific filling-head number and particular cylinder volume,based on the user’s production demand. 6-head, 8-head and 10-head can be chosen.The cylinder volume can be chosen from 25-250ml, 50-500ml, 100-1000ml and 250-2500ml. The whole machine is speed-adjustable.

- 10. Considering the different viscosity of user’s material ,we especially set a special filling valve to adjust to different situations. and We also designed a descending filling lift system. In order to make the material-falling accurate at the bottle mouth , we designed a horizontal bottle-aiming fixture device.

- 11. The machine set a weight filling program to fix the flow parameter and makes the machine adjustable to the complicated material varieties. The system can realize the one-machine multi-use without other parts and decrease the equipment’s repeated investment.

View Video

Advantage of Liquid Soap Filling Machine

The 50-1000ml Liquid Soap Filling Machine is suitable for low viscous liquid bottles containers that are less than 1000ml in volume. With an automatic bottle unscrambler, filling machine, rotary capping machine and gluing/self-adhesive labeling machine, the chemical packaging line is a complete production line that packages and seals cartons. This effective bottle packaging machine is adjustable to fill low viscous liquids such as cleaners, detergent,liquid soaps and other low viscous liquid and applies anti-theft caps.

- The unit is made compact & versatile.

- S.S. Slat conveyor.

- S.S. Elegantly Matt Finished Body.

- No Container No filling system.

- Reciprocating Filling nozzle with self centring device.

- Variable A/c Frequency Drive.

- Pneumatically operated bottle stopper.

View Video

Integrate a Full System of Liquid Soap Filling Machines

- To fill a viscous liquid like soap, specialized liquid packaging machines are required. We offer a variety of machinery to meet the requirements of your specific application. Based on your production line’s specifications, we can assist with the selection of reliable equipment that best suits your facility. Our inventory includes a range of liquid soap filling machines and many other types of equipment that can complete your packaging system

- Upon completion of the liquid filling process, capping machines can place custom-fitted caps on product containers. Labeling machines can apply unique labels with branding, images, and text to containers. A complete system of conveyors is customizable to meet the application’s speed requirements, with fully programmable settings. A system comprised of a combination of this equipment can maximize productivity and accuracy during the liquid packaging process. All of our equipment is manufactured using top-quality materials that can reduce breakdowns and minimize maintenance costs.

View Video

Advanced design

- 1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

- 1.2 Short filling circle, high production capacity.

- 1.3 Changing filling circle, high production capacity.

- 1.4 User may choose the filling volume and decide the filling heads per own production capacity.

- 1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

- 1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

View Video

Customize Your Production Line

- All of the machinery available at VKPAK Machinery, including liquid soap filling equipment, is customizable to work with your packaging system. Choose from various sizes and program settings to make integration simple and effective. Our team of knowledgeable and experienced experts can help you with machine selection and installation to ensure successful implementation.

- If you would like to start designing and installing a customized system of liquid soap filling machines and more, contact VKPAK Machinery. To further improve your production line, we offer a selection of services that contribute additional support to keep your production line efficient. Our services include field service, high-speed cameras, performance improvement, leasing, and operator training. A combination of our packaging machinery and services can keep your production line consistently effective for many years.