Peanut Oil Filling Machine

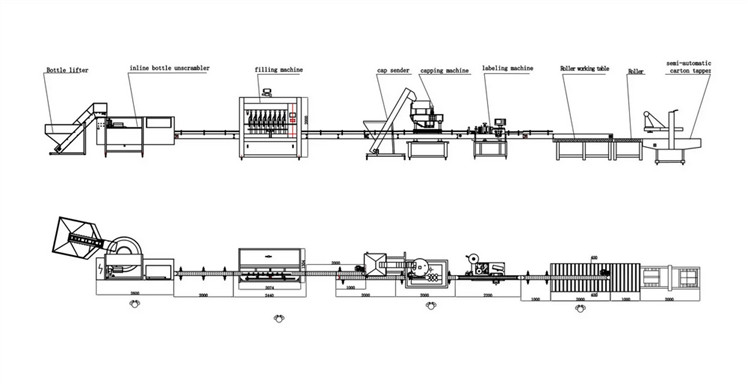

This automatic Peanut Oil Filling Machine line comes with everything you need to get your liquid sweetener bottling line up and running. It is designed to bottle 50 bottles per minute. Start your project today by clicking request a quote below!

Line Name: Automatic Peanut Oil Filling Machine line

- Automation: Automatic

- Filling volume:500-5000ml

- Bottles Per Minute: 20-50

Configuration List

| Descriptions | Brand | Item | Remark |

| Servo motor | Panasonic | 1.5KW | Japan |

| Reducer | Fenghua | ATF1205-15 | Taiwan |

| Conveyor motor | ZhenYu | YZ2-8024 | China |

| Servo drivers | Panasonic | LXM23DU15M3X | Japan |

| PLC | Schneider | TM218DALCODR4PHN | France |

| Touch Screen | Schneider | HMZGXU3500 | France |

| Frequency Converter | Schneider | ATV12HO75M2 | France |

| Photo electricity of inspect bottle | OPTEX | BRF-N | Japan |

| Pneumatic Element | Airtac | Taiwan | |

| Rotary Valve | F07/F05 | No Need for Oil | |

| Pneumatic actuator | F07/F05 | No Need for Oil | |

| Low-Voltage Apparatus | Schneider | France | |

| Proximity switch | ROKO | SC1204-N | Taiwan |

| Bearing | China | ||

| Lead Screw | TBI | Taiwan | |

| Butterfly valve | CHZNA | China |

Technical Parameters

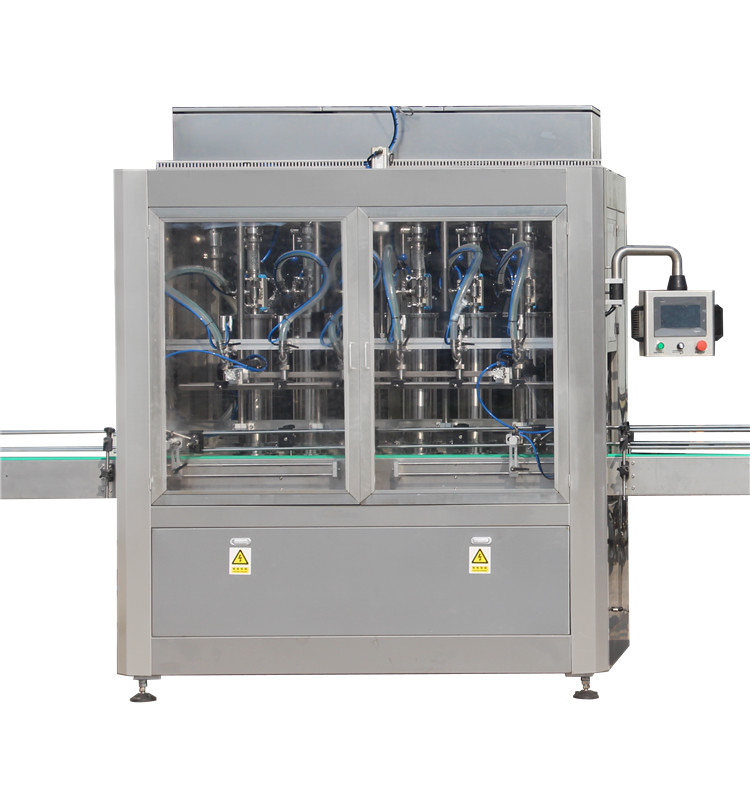

| Filling Nozzles | 1-16Nozzles |

| Production Capacity | 800 -5000Bottles Per Hour |

| Filling Volume | 100-500ml,100ml to 1000ml, 1000ml to 5000ml |

| Power | 1500W to 3000W, 220VAC |

| Accuracy | ±0.1% |

| Driven | Panasonic Servo Motor |

| Inerface | Schneider Touch Screen |

Features of Peanut Oil Filling Machine

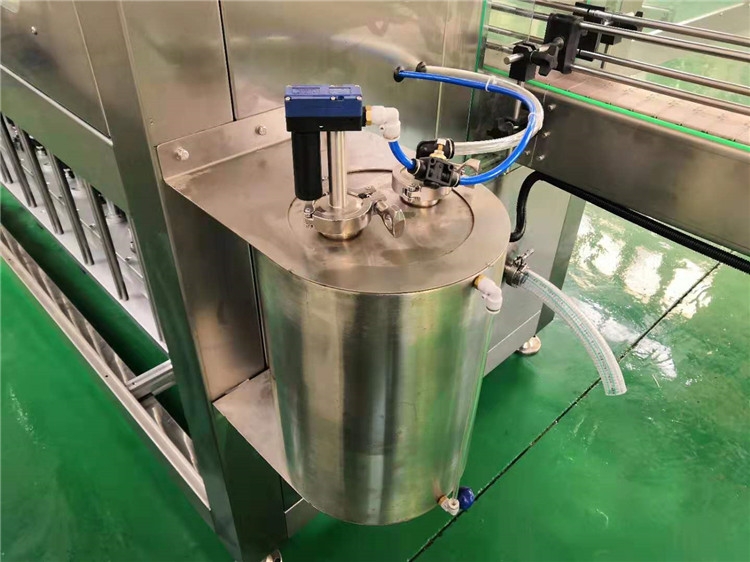

- Drip free nozzles with drip tray for accidental drip.

- Non contact electronic sensor to ensure “no bottle no fill” system.

- PLC system with E100 HMI two line LCD displays and VFD control of C.G. make for conveyor speed control.

- German measuring chamber for better repeatability of 0.05%. Having in built non liquid contact sensor for measuring rotation of chamber.

- Body frame made up of M.S. with Powder coating.

- Capable of automatic intake of empty bottles / container on to the filling station and discharge after filling bottles with the help of stop and release lever pneumatically operated.

- Fast flow and fine flow system for better accuracy, interval can be steed form PLC, Volume would be steed individually for each nozzle with a increment of 1ml.

- Neck entry system so that the nozzle enter inside the container before filling to avoid spillage.

- 16 feet conveyor with 12 inches stainless steel slats and suitable for filling containers along with electric motor for main drive and conveyor reduction gear box and variable frequency drive.

- Enclosed body with transparent Acrylic doors in front and back

- Pneumatically operated Nozzle Up-Down movement & stopper Gates for bottle entry and exit.

- Adjustment can be made without interrupting filling sequence.

- Manual valve on bypass line of pump.

- Vane pump of 200 LPM

- In built memory to store 25 filling setting data.

- Filling accuracy of +/- 0.25%

Scope of Application

- This filling machine is used for quantitative filling various oils. We have the pneumatic filling machine and electric filling machine, automatic and semi-automatic oil filling line.

- Oil filling machine is suitable for the quantitative automatic liquid filling, can fill various oils, such as lubricating oil, edible oil, cooking oil, and drinks. It can fill oil in different sizes of bottles.