Lip Balm Filling Machine

- For a selection of reliable lip balm filling machines, turn to VKPAK Machinery for your liquid packaging system needs. We carry a wide range of machinery to install in many different types of liquid packaging facilities, including lip balm products. Along with liquid fillers, we also offer a variety of cappers, labelers, and conveyors that can provide top-quality performance with durable construction and easy operation.

Lip Balm Filling Line Description

- This lip balm filling line comes with a tube unscrambler and pucker, molten filling machine, remelter, cap elevator, cap sorter, snap capping machine, bottom coding and depucker as well as all the conveyor necessary. This line is capable of filling many different sizes and shapes of lip balm as well as many different recipes.

Feature for Lip Balm Filling Machine

- Process(Preheating->filling->remelting->chilling).

- Low manpower cost, and energy saving.

- Simple to clean and change different colors and formula.

- Easy to operate and set parameters on touch screen.

- Highly outputting.

- Practically to fill the materials which including glitters&pearl powder.

Install a Complete Lip Balm Filling Equipment System

- Lip balm is one of the more viscous substances that VKPAK Machinery equipment is designed to fill and package. Our inventory includes a selection of gravity fillers, overflow fillers, and other types of filling machines that can meet the needs of most liquid products. For other aspects of liquid packaging systems, we offer other types of equipment.

- Following completion of the liquid filling process, your production line can use a capper to effectively seal lip balm containers, labelers to apply clear, paper, or Mylar labels with custom graphics and text, and conveyors that can transfer containers between stations at various speeds. With a combination of our liquid filling and packaging machinery integrated in your facility, you can benefit from improved efficiency and productivity.

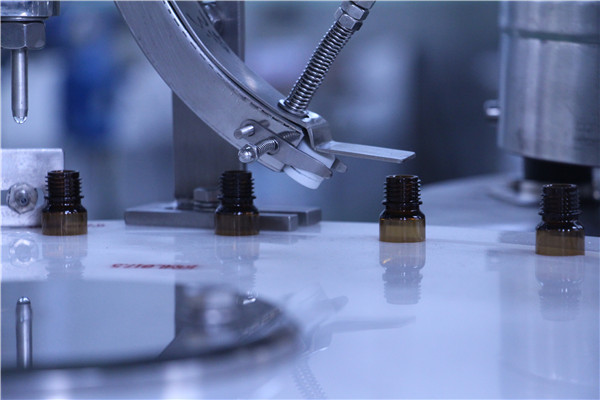

Flexible

- Exceptional flexibility adapts to small bottles

- E-cigarette fluids, eye drops and penicillin products

- Conveyor has adjustable guide rails and replaceable star wheels to suit different product configurations

Efficient

- Low energy consumption, high throughput

- Integrated touch-screen controls for ease of use and high productivity

- Volume Set feature to control all pistons through Servo System

- Volume for each piston can be set with one touch on screen – no manual adjustment required

Practical

- Management setting with password protection to restrict access

- Fully enclosed, easy to manage quick changeovers

- Built in mobility castors to make efficient use of floorspace