Cosmetic Cream Filling Machine

- Cosmetic products can range from thin liquid products such as perfume and baby oils to thicker creams and lotions for skin care and hair. In an industry that serves a large variety of product types, no single filling machine will normally work for all of the products. When it comes to cosmetics, there are several different liquid fillers that are ideal for the different creams and lotions offered by the industry.

- To maximize efficiency and productivity in your cosmetics production line, consider installing a system of cosmetic filling machinery form VKPAK Machinery in your facility. We offer a variety of liquid filling machines that can meet the requirements of facility space restrictions, with a selection of cappers, conveyors, and labeling machines also available. A custom combination of machines can make your facility less vulnerable to breakdowns and increase productivity.

OVERFLOW FILLER

- As we have discussed before, overflow fillers allow for an aesthetic fill that is ideal for products bottled in clear containers. While the overflow filler can work with some thinner creams and lotions, it is not always the best solution for these products. This type of liquid filler relies, in general terms, on overflowing the container, with excess product returning to a holding tank through the unique nozzles. But when a thicker product is used, fill times may increase slightly. The choice to use this type of filling machine for lotions and creams will normally come down to balancing the value of the level fill against the possible extra time required each cycle to achieve such a fill.

PUMP FILLER

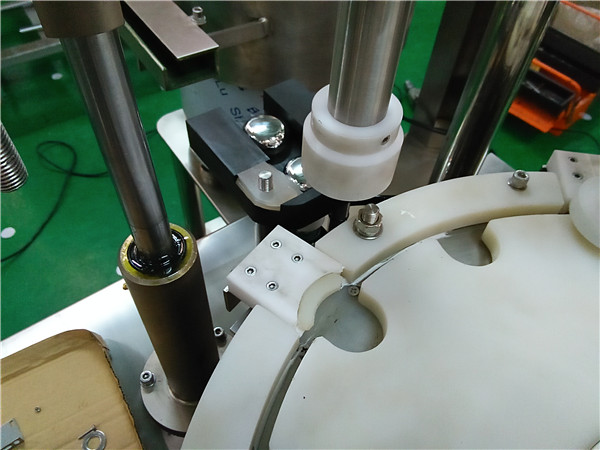

- Pump filling machines are often ideal for creams and lotions found in the cosmetic industry. These liquid fillers can handle thicker products through the use of several different pumps and nozzles. The ability to move thicker products with a pump matched to the product itself, along with the flexibility to use many different types of heads, makes the pump filler a versatile piece of packaging equipment. However, these machines will require a pump for each and every fill head in use.

PISTON FILLER

- Piston fillers are also versatile filling machines in that they can handle a wide range of product viscosities while providing an accurate volumetric fill. For thick creams and lotions, the piston may work better than either of the two fill principles noted above. For companies filling cosmetic products ranging from low to very high viscosities, this machine can sometimes provide a solution for all products, depending on a number of factors, including speed, bottles or other containers and the characteristics of the products themselves.

- Each of the filler types described above can be manufactured to run automatic production for high speed facilities or can be built as semi-automatic machines for cosmetic companies with lower demands. Finding the ideal solution will entail a simple analysis of product, package and production needs.

Install a Complete Cosmetic Filling Equipment System

- Cosmetic products have varying levels of viscosity, which is why you should make sure you install the right liquid filling machinery in your facility to get the results you want. Overflow fillers, piston fillers, pump fillers, and gravity fillers are available depending on viscosity. Whether you have an assembly for gels, lotions, ointments, pastes, creams, or other types of liquid cosmetics, we have cosmetic filling equipment that can handle these products and keep your production line moving smoothly.

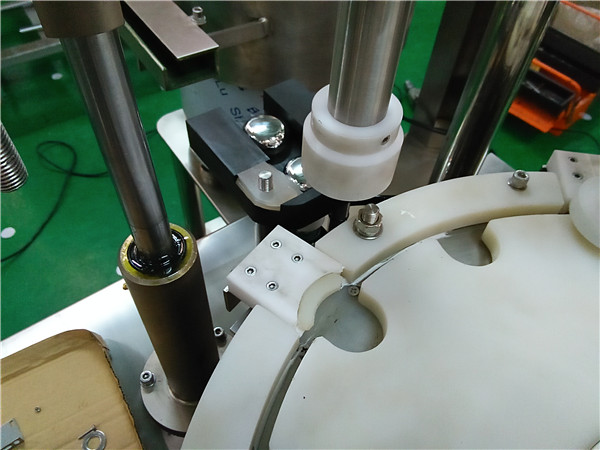

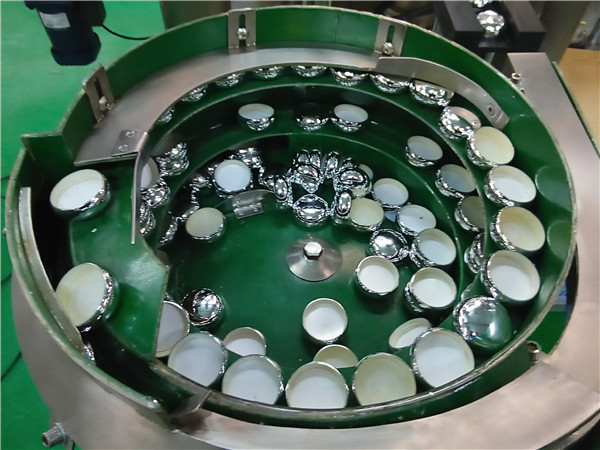

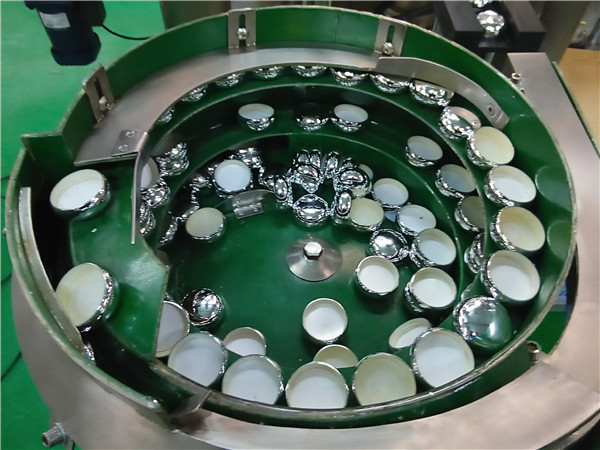

- Following the liquid filling process, other types of equipment can maintain efficiency of the packaging process all the way through to completion. Capping equipment can apply caps of different shapes and sizes to a wide range of containers, labelers can apply high-quality labels with custom graphic and text, and conveyors can transfer products at varying speeds between stations.

Design a Custom Production Line for Cosmetics

- To meet the specific requirements of your application, we can help you design a customized system of cosmetic filling equipment. Choose from different sizes and configurations to optimize the liquid packaging process, with help from one of our packaging experts. We can also help you install your custom liquid filling line and test it to make sure it’s capable of giving you the results you want to see.

- If you want to get started on the design and implementation of custom cosmetic filling machinery, speak with one of the experienced staff at VKPAK Machinery. We can help ensure that your production line provides years of consistently high-quality service, with minimal risk of mechanical issues breakdowns. Along with reliable liquid filling equipment, we also offer additional services including installation, leasing, and field service. We also offer high-speed camera services, which can provide a closer look at operations and help determine what steps you can take to improve your equipment’s performance.

Contact VKPAK machinery

- Our cosmetic liquid filling machines are specifically built to meet the constantly changing demands of the cosmetics industry. We are continuously striving to make our cosmetic filling equipment able to accommodate more container shapes and sizes. Our goal is to manufacture the best machines that are able to handle various levels of viscosity.