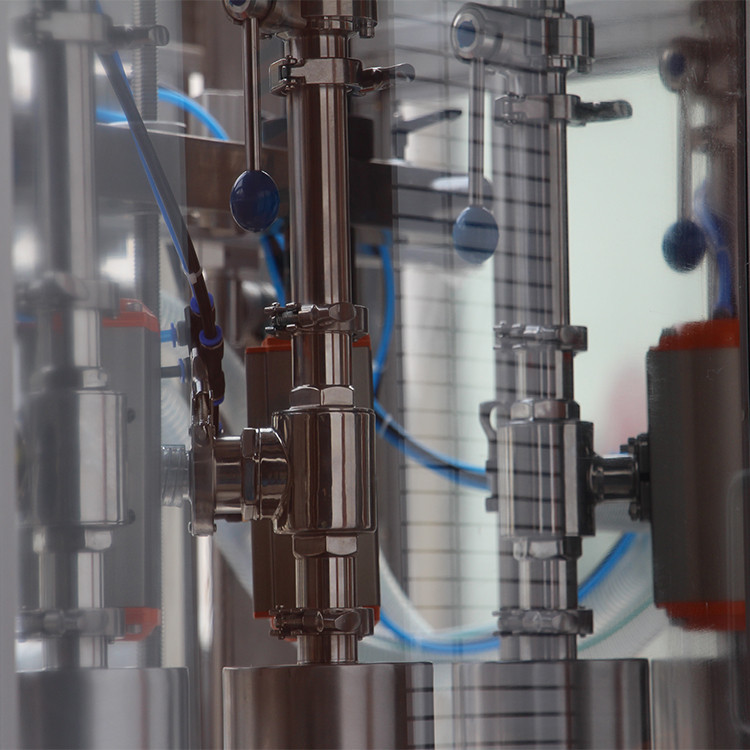

Chemicals Filling Machine

- When you are bottling Chemical there are several types of filling machines you may choose.

- Our Chemical liquid filling machines are designed to meet the changing needs of the Chemical industry. We manufacture the ideal machinery to handle your Chemical filling needs and meet your production goals.

View Video

For all your chemical needs

- Material compatibility is crucial when handling liquid chemicals. At VKPAK our staff have many years of experience in dealing with a wide variety of chemical products and our machines have been designed to accommodate this diverse range of products.

- Hoses and seals are available in Viton, EPDM, PTFE, Kalrez and Nitrile.

- Machine components are generally manufactured in stainless steel, although glass and plastics are used for handling acid and alkaline products where stainless steel is not suitable.

- From free flowing solvents through to viscous adhesives, our range of machines will be able to handle most chemical products from 5ml up to 5 litres as standard and up to 25 litres with the additional multi-dose counter.

View Video

Toilet Cleaning Liquid Filling Machine Features

This non-metal filling machine specially designed for strong acid and alkali product, such as: hydrochloric acid products bleach.

- PLC controlled, friendly touch screen control.

- Famous brand electrical and pneumatic components used to guarantee machines quality and long life service time.

- Vacuum suck back for dripping can be special designed for foamy product.

- All wetted parts are made of non-metal materials, anti-corrosion.

- Not only whole filling heads can be adjusted, but each filling head can be fine-adjusted respectively.

- Bottle inlet counting, quantitative filling, bottle outlet counting, and serious motions can be done automatically.

- Simple structure, easy operation, Low noise, reliable running, accurate filling.

View Video

Advantage of Toilet Cleaning Liquid Filling Machine

- Use strong and long life PVC material

- PLC control, and adjust the filling volume by touch screen

- Low cost for investment

- Diving filling head to anti foamy

View Video

Utilize a System of Chemical Filling Machines

- VKPAK Machinery’s chemical filling equipment is designed for a wide range of chemicals and containers. Our gravity, piston, overflow, pressure, and pump fillers are available with custom options to provide the best results for production lines. With a complete system of chemical filling machines that meet your needs, you’ll benefit from maximized efficiency and accuracy.

- We offer other types of liquid packaging machinery to further improve your packaging assembly, including bottle cleaners, conveyors, labelers, and cappers. Each piece of equipment can make the packaging process as effective as you need it to be, giving you top-quality results for each product.

View Video

Installing Custom Chemical Packaging Systems

- If you require a complete packaging assembly for chemical products apart from chemical filling equipment, we provide liquid packaging equipment that can handle many types of chemicals. We have the machinery you need to keep your production line functioning optimally.

- Use bottle cleaners to clear chemical bottles of dust particles and other potential contaminants prior to filling. After filling machines are used to accurately fill containers, cappers can place custom-fitting caps of various sizes and shapes to bottles, forming an airtight and leak-proof seal. Labelers can apply clear, paper, or Mylar labels to bottles with detailed text and images displaying product information and branding. To make sure each product is successfully transferred between stations, a system of conveyors can transport products from the beginning of the line to the end when ready for shipping.

View Video

Consult VKPAK Machinery for Custom Packaging Solutions

- For assistance with machine selection and design, VKPAK Machinery’s technical experts are available to help. We can develop a customized system that gives you consistent results, with a configuration that meets space requirements and product specifications. We understand that different types of chemicals and manufacturing facilities will require varied installations to function properly. To ensure equipment is sufficiently set up, we’ll install equipment nearly anywhere in the U.S.

- Along with machine selection, system design, and installation, we also offer many other services to keep your production line working the way it should. Our services include leasing, field service, and high-speed camera services that can improve your equipment’s overall performance and staff productivity.

- To get started on the design and installation of your chemical filling machine system, along with a complete liquid packaging assembly, contact VKPAK Machinery.