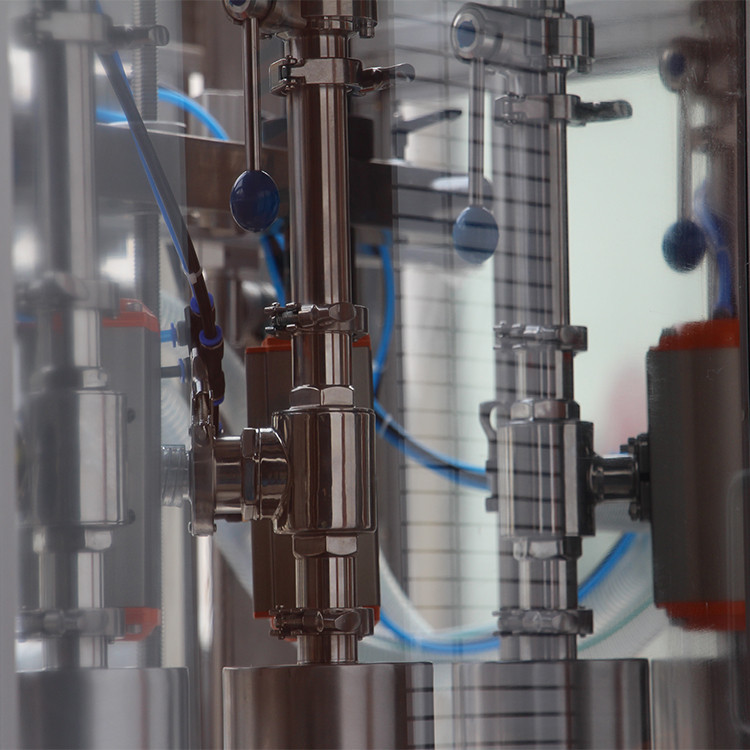

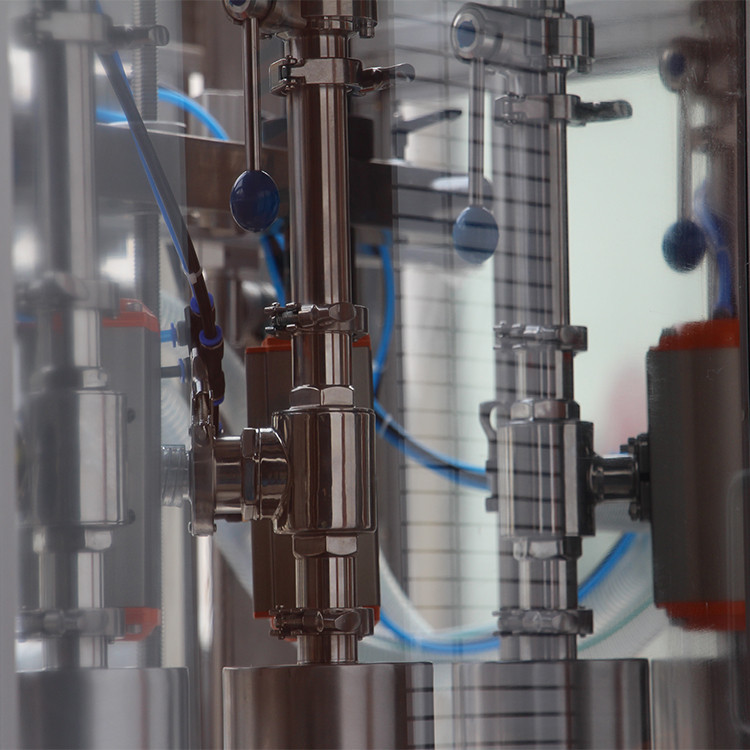

Solvent Bottle Filling machine

- Material compatibility is crucial when handling liquid chemicals. At VKPAK our staff have many years of experience in dealing with a wide variety of chemical products and our machines have been designed to accommodate this diverse range of products.

- Hoses and seals are available in Viton, EPDM, PTFE, Kalrez and Nitrile.

- Machine components are generally manufactured in stainless steel, although glass and plastics are used for handling acid and alkaline products where stainless steel is not suitable.

- From free flowing solvents through to viscous adhesives, our range of machines will be able to handle most chemical products from 5ml up to 5 litres as standard and up to 25 litres with the additional multi-dose counter.

- Screw on, twist on, push on and ROPP caps can all be accommodated on our range of Capping Machines.

Solvent Bottle Filling machine Introduction

- All the machine material are constructed by PVC to anti corrosive including the conveyor, control box.

- Schneider PLC control, and Schneider touch screen operation it is easy for changing size or modifying parameters.

- Pneumatic elements are all imported, stability and reliability.

- Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

- Close positioning design, easy governing, suitable for packing of all sizes of bottles.

Solvent Bottle Filling machine Features

This non-metal filling machine specially designed for strong acid and alkali product, such as: hydrochloric acid products bleach.

- PLC controlled, friendly touch screen control.

- Famous brand electrical and pneumatic components used to guarantee machines quality and long life service time.

- Vacuum suck back for dripping can be special designed for foamy product.

- All wetted parts are made of non-metal materials, anti-corrosion.

- Not only whole filling heads can be adjusted, but each filling head can be fine-adjusted respectively.

- Bottle inlet counting, quantitative filling, bottle outlet counting, and serious motions can be done automatically.

- Simple structure, easy operation, Low noise, reliable running, accurate filling.

Advantage of Solvent Bottle Filling machine

- Use strong and long life PVC material

- PLC control, and adjust the filling volume by touch screen

- Low cost for investment

- Diving filling head to anti foamy

Automatic Solvent Bottle Filling machine System

- Rinsing System

- Detergent filling equipment applies unique overturning bottle clamp, which is hygienic and durable. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

- Filling System

- Clip the bottle neck with steel starwheel. There is no need to adjust the equipment height when changing the bottle shape whose diameters have no much change.

- Rotating disks all make from stainless steel. Large planar toothed bearings can ensure the stable operation of machine.

- High-precision electronic liquid level filling valve makes fast and slow fillings possible.

- Automatic washing cup can circularly and thoroughly clean the filling valve through CIP cleaning program.

- Integrate filling valve with bottle lifting mechanism. The simplified structure makes cleaning easier and could improve the stability of the machine. Bottleneck is clipped by clippers.

Advanced design

- 1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

- 1.2 Short filling circle, high production capacity.

- 1.3 Changing filling circle, high production capacity.

- 1.4 User may choose the filling volume and decide the filling heads per own production capacity.

- 1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

- 1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

Specification

| Name | Solvent Bottle Filling machine |

| Model | VK-PF |

| Filling Nozzles | 2-12 nozzles, or customized |

| Applied bottle range | 30-100ml, 100-1000ml, 900ml-5000ml |

| Material density | 0.6-1.5 |

| Tolerance of filling quantity(accuracy) | ±£0.1% |

| Filling speed | 800-4200 bottles/hour , 30b/min per 4 filling nozzles 1L |

| Power | 2KW |

| Voltage | 220V,380V ,50HZ /60HZ |

| Air Pressure | 0.6Map |

| Air Consumption | 1.2-1.4m³/min |

| Weight | 400kg |

| Dimension | 2200*1400*2300mm |

| Control | PLC,TOUCH SCREEN |

After-sales Service

- (1) Under stable voltage, the machines’ quality that we sold will be guaranteed for 1 year

- (2) Long time technology will be supplied.

- (3) We can dispatch our engineer to your side for installing and debugging machines. Engineer’s round-trip tickets, accommodation, and your side traveling fee will be charged by you. Engineer’s salary will be USD60.00/day/person.

- (4)We can also supply training process for your engineers who come to china, so you can fit and debug machines by yourself.