Shoe Polish Filling Machine

- When you are bottling Nail Polish there are several types of filling machines you may choose.

- VKPAK designs and builds filling machines and packaging equipment for Nail Polish.

- Our Nail Polish liquid filling machines are designed to meet the changing needs of the Nail Polish industry. We manufacture the ideal machinery to handle your Nail Polish filling needs and meet your production goals.

Shoe Polish Filling Machine Introduction

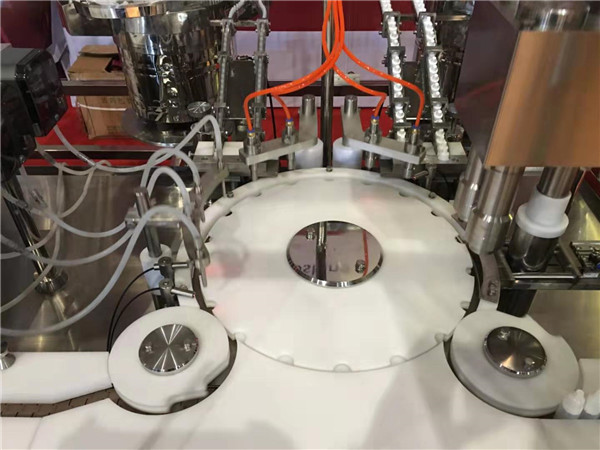

- This machine applies the transmission principle. It uses the slot wheel dividing system to drive the conveyor table to do intermittent movement. The machine has 8 or 10 tube stations. Expect manually feeding the tubes onto the machine, it can automatically position the tubes, fill the material into the tubes, heat both inside and outside of the tubes, seal the tubes, press the codes, and trim the tails and the finished tubes exit.

Feature

- Filling measurement is accurate by the pistol plunger. Heating time is stable and adjustable. Sealed tail looks pretty and neat and the trimming is very even. This machine has stable performance and has no any noise and pollution during production.

- The part which is contact with the filling material is made of high-quality stainless steels 304 or SS316L. The parts which need to clean are made of quick-change device that is removable and convenient for washing.

- If some materials need heating insulation, the heating thermostat device can be added outside of the feeding barrel.

Working Flow

- Manually feeding the tubes

- Automatic mark positioning (photoelectrical sensor)

- Automatic dosing filling

- Tail inner heating

- Tail sealing and pressing the batch, dates

- Tail trimming

- Automatic ejection

Technical Parameters

| Tube type | Metal tubes |

| Sealing | Different folding styles |

| Max. Diameter | 35mm |

| Capacity | 30-60tubes/min |

| Filling precision | ±0.1% |

| Volume | 1-150ml |

| No. Stations | 9Stations 6,7 RPM |

| Voltage(V) | 220,380,440 |

| Frequency | 50/60Hz |

| Motor Power | 1.1KW |

| Compress Air | 0.4-0.6mpa |

Flexible

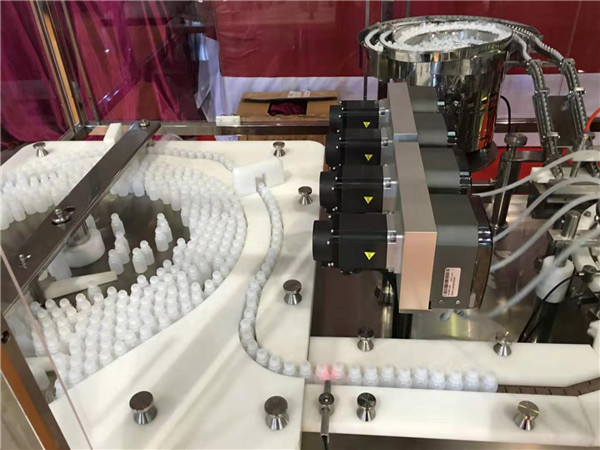

- Exceptional flexibility adapts to small bottles

- E-cigarette fluids, eye drops and penicillin products

- Conveyor has adjustable guide rails and replaceable star wheels to suit different product configurations

Efficient

- Low energy consumption, high throughput

- Integrated touch-screen controls for ease of use and high productivity

- Volume Set feature to control all pistons through Servo System

- Volume for each piston can be set with one touch on screen – no manual adjustment required

Practical

- Management setting with password protection to restrict access

- Fully enclosed, easy to manage quick changeovers

- Built in mobility castors to make efficient use of floorspace