Powder Filling & Sealing Machine

- Are you in the market for packaging solutions for powders? VKPAK offers a powder filling machine line which is ideal for everything from chemicals to spices. We supply both automatic and semi-automatic equipment which has been proven to be safe and effective.

- Our auger filler machines and vertical form fill and seal machines ensure products like sugar, powdered milk, detergent, and flour are packaged accurately. Whether you have a new production facility, you’ve expanded your product range, or you need to replace older equipment, a modern powder filling machine will enhance your operations. It will enable you to package your product more efficiently and streamline your production

View Video

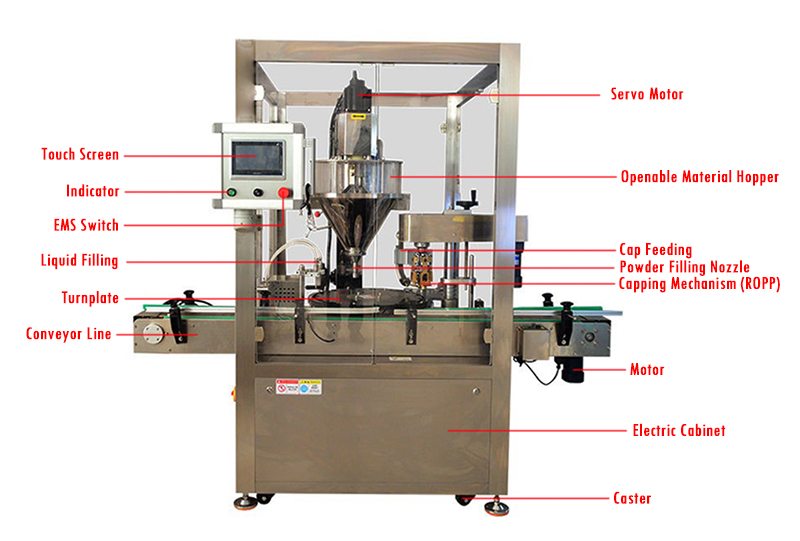

Automatic Powder Filling&Sealing Machine Description

- The VK-PAF Automatic powder auger filling and capping machine is application for automatic filling powder

- Into the bottles, vials and cans, then automatic capping(sealing) the bottles. It is monoblock machine.

- The main products are glitter powder, pepper, cayenne pepper, milk powder, rice flour, albumen powder,soy milk powder, coffee powder, medicine powder ,additive, essence and spice, etc It can connnect with a bottle feeding table or bottle unsrambler from start, and connection with VK-VRL round bottle labeling machine or VK-DSL double side labeling machine being a full automatic packaging lines.

View Video

Feature

- Compact GMP model.

- The unit is made compact & versatile as per current norms.

- All contact parts made from high quality Stainless Steel 316.

- Machine body is elegantly matt finished from Stainless Steel 304.

- Slat conveyor belt made from Stainless Steel 304.

- “No Cartridge – No Filling” system to avoid wastage of costly liquid.

- High filling accuracy of ±0. 1% in single dosing.

- Plugging without leaving plug on cartridges.

- Latest design picks up system.

- All three operations on one platform, hence less space requirement.

View Video

Advantage

- 1.Servo motor driven, Siemens PLC and touch screen

- 2.Adapt with automatic powder feeder to feed powder into hopper

- 3.Equipped with dust cover and dust suction system when filling the powder.

- 4.IT increase the filling nozzle and capping head to increase the working capacity

View Video

Technical Parameters

| Model | VK-PAF-1 | VK-PAF-2 |

| Bottle diameter | Φ15-80mm(customize) | |

| Bottle height | 15-150mm(customize) | |

| Filling Weight | 1 – 5g,5-30g,30-100,100-500g | |

| Filling Accuracy | ≤ 100g, ≤±2%; 100 – 500g,≤±1% | |

| Filling Speed | 15 - 35bottles/min | 30 - 70 bottles/min |

| Power Supply | 3phase AC380V 50/60Hz | |

| Air Supply | 6 kg/cm2 0.05m3/min | |

| Total Power | 1.8Kw | 2.3Kw |

| Total Weight | 450kg | 550kg |

| Overall Dimensions | 1400×1120×1850mm | 1700×1420×2000mm |

| Hopper Volume | 35L | 25L(two hoppers) |

View Video

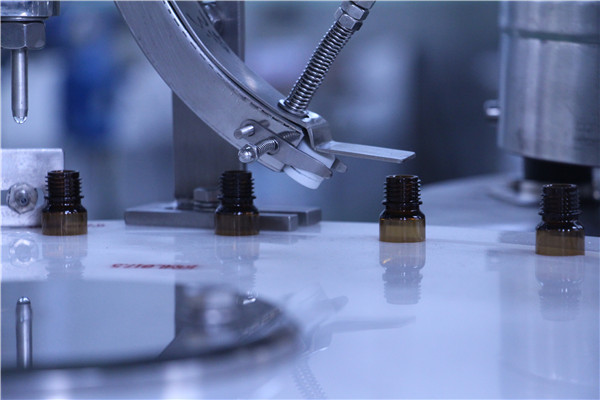

Flexible

- Exceptional flexibility adapts to small bottles

- E-cigarette fluids, eye drops and penicillin products

- Conveyor has adjustable guide rails and replaceable star wheels to suit different product configurations

View Video

Efficient

- Low energy consumption, high throughput

- Integrated touch-screen controls for ease of use and high productivity

- Volume Set feature to control all pistons through Servo System

- Volume for each piston can be set with one touch on screen – no manual adjustment required

View Video

Practical

- Management setting with password protection to restrict access

- Fully enclosed, easy to manage quick changeovers

- Built in mobility castors to make efficient use of floorspace