Pesticide Filling Machine

- The 50-1000ml pesticide filling machine is suitable for low viscous liquid bottles containers that are less than 1000ml in volume. With an automatic bottle unscrambler, filling machine, rotary capping machine and gluing/self-adhesive labeling machine, the chemical packaging line is a complete production line that packages and seals cartons. This effective bottle packaging machine is adjustable to fill low viscous liquids such as cleaners, detergent,liquid soaps and other low viscous liquid and applies anti-theft caps.

Pesticide Filling Machine Introduction

- All the machine material are constructed by PVC to anti corrosive including the conveyor, control box.

- Schneider PLC control, and Schneider touch screen operation it is easy for changing size or modifying parameters.

- Pneumatic elements are all imported, stability and reliability.

- Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

- Close positioning design, easy governing, suitable for packing of all sizes of bottles.

Pesticide Filling Machine Features

- 1. Only need three people (one operator, two assistants) to operate this production line.

- 2.Fast and efficient unscrambler is suitable for flat and round bottles and easy to adjust for size. Fallen bottles will be returned to the elevator and the unscrambler will alert operator to unfilled bottles.

- 3. Servo volumetric filling machine is highly precise. Filling nozzles automatically adjusts to different bottles and reduce foam.

- 4. The rotary capping machine is 100% qualified and rejects dented or broken caps.

- 5. The automatic carton opening and sealing machines are easy to operate and speed up production.

Advantage of Pesticide Filling Machine

- Use strong and long life PVC material

- PLC control, and adjust the filling volume by touch screen

- Low cost for investment

- Diving filling head to anti foamy

Pesticide Filling Machine System

- Rinsing System

- Detergent filling equipment applies unique overturning bottle clamp, which is hygienic and durable. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

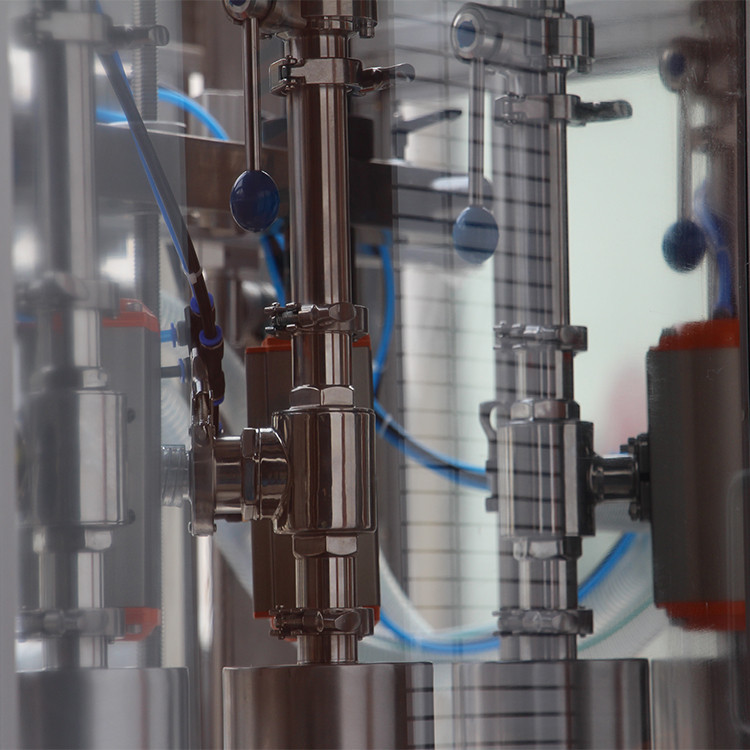

- Filling System

- Clip the bottle neck with steel starwheel. There is no need to adjust the equipment height when changing the bottle shape whose diameters have no much change.

- Rotating disks all make from stainless steel. Large planar toothed bearings can ensure the stable operation of machine.

- High-precision electronic liquid level filling valve makes fast and slow fillings possible.

- Automatic washing cup can circularly and thoroughly clean the filling valve through CIP cleaning program.

- Integrate filling valve with bottle lifting mechanism. The simplified structure makes cleaning easier and could improve the stability of the machine. Bottleneck is clipped by clippers.

Advanced design

- 1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

- 1.2 Short filling circle, high production capacity.

- 1.3 Changing filling circle, high production capacity.

- 1.4 User may choose the filling volume and decide the filling heads per own production capacity.

- 1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

- 1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

Pesticide filling machine Main performance parameters

- 1. Capacity: 50ml -100ml ≤ 6000b/h; 500ml ≤5000b/h; 1000ml≤4500b/h

- 2. Bottle type: round bottle Φ40-100 mm, height 80-280 mm flat bottle (40-100mm)*(40-100mm)*(80-280mm)(L x W x H)

- 3. Diameter of bottle opening: ≥φ25mm

- 4. Filling range: 50-1000ml

- 5. Precision: (1000ml)±0.1%

- 6. Air pressure: 0.6~0.8 MPA

- 7. Power source: ~380V,50HZ

- 8. Production line height: 900mm±50mm

- 9. Filling materials: liquid soap, cleaners and low viscous liquid packing

- 10. Bottle feeding direction: From left to right