Machine Oil Filling Machine

- This is an oil filling machine mainly useful in filling of oil in plastic bottles, glass bottles and even metal containers. The applications of such oil filler machines include the ability to fill several types of oil, like vegetable oil filling machine, edible oil filling machine, cooking oil filling machine, lubricant oil filling machine. In addition to that this machine has several good features including a no drip feature and the ability to make adjustments on they fly. It is a highly efficient machine with good performance that does not cost a lot to maintain.

View Video

lube Oil Filling Machine Introduction

- The 50-1000ml lubricant oil filling machine is suitable for low viscous liquid bottles containers that are less than 1000ml in volume. With an automatic bottle unscrambler, filling machine, rotary capping machine and gluing/self-adhesive labeling machine, the chemical packaging line is a complete production line that packages and seals cartons. This effective bottle packaging machine is adjustable to fill low viscous liquids such as cleaners, detergent,liquid soaps and other low viscous liquid and applies anti-theft caps.

- This machine is also known as engine oil filling machine, engine oil packing machine, motor oil filling machine, lube filler, lube oil filler, lube packing machine, motor oil filler, motor oil filling machine, motor oil packing machine, motor oil filling machine

View Video

Machine Oil Filling Machine Features

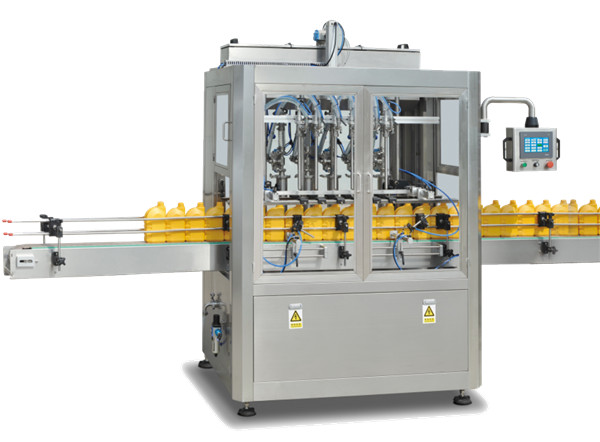

- 1 Machine Oil Filling Machine is designed to be compact and reasonable.

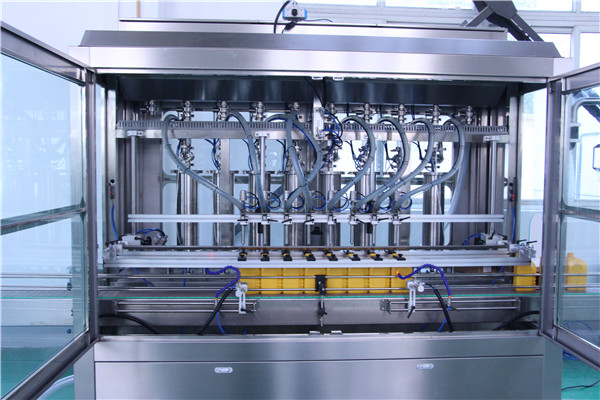

- 2 Choosing the international brand of electrical components. The main powered cylinder, chose the Taiwan Airtac double-action cylinder and magnetic switch, the Japanese Mitsubishi PLC computer, photo electricity and Taiwan-manufactured touching screen, ensuring a good quality and lasting steady performance.

- 3 Convenient maintenance without any tools. This machine can be dispart, cleaned and fixed easily.Filling precision and quantity are adjustable and should be regulated among a big range firstly,then be trimmed.

- 4 We can customize the filling machine with specific filling-head number and particular cylinder volume,based on the user’s production demand. 6-head, 8-head and 10-head can be chosen.The cylinder volume can be chosen from 25-250ml, 50-500ml and 100-1000ml. The whole machine is speed-adjustable.

- 5 Considering the different viscosity of user’s material ,we especially set a special filling valve to adjust to different situations. and We also designed a descending filling lift system. In order to make the material-falling accurate at the bottle mouth , we designed a horizontal bottle-aiming fixture device.

- 6 The machine set a weight filling program to fix the flow parameter and makes the machine adjustable to the complicated material varieties. The system can realize the one-machine multi-use without other parts and decrease the equipment’s repeated investment.

View Video

Advantage of Machine Oil Filling Machine

- Use strong and long life PVC material

- PLC control, and adjust the filling volume by touch screen

- Low cost for investment

- Diving filling head to anti foamy

View Video

Machine Oil Filling Machine System

- Filling machines for the oil and lube business are the same as those used to fill liquid soaps. Depending on the range of viscosities of the producer’s product line, a piston filling machines is generally used. A product line that includes heavy greases would definitely use a piston filler. A product line that only fills lighter motor oils can be filled in a piston filler, an an overflow filling machine, or a servo pump machine. Because these products are sold volumetrically, the overflow filling machine is used infrequently as the container might possibly give away product due to expansion of the container under pressure. Although the piston filler is a more common machine in this industry, the servo pump filling machine has found increasing favor because petroleum based oils volumes vary significantly with ambient filling temperature and piston fillers require more adjustments in this regard.

- Rinsing System

- Detergent filling equipment applies unique overturning bottle clamp, which is hygienic and durable. This bottle clamp grips bottle at neck position, avoiding bottle mouth thread contamination caused by rubber gripper block of a traditional bottle clamp.

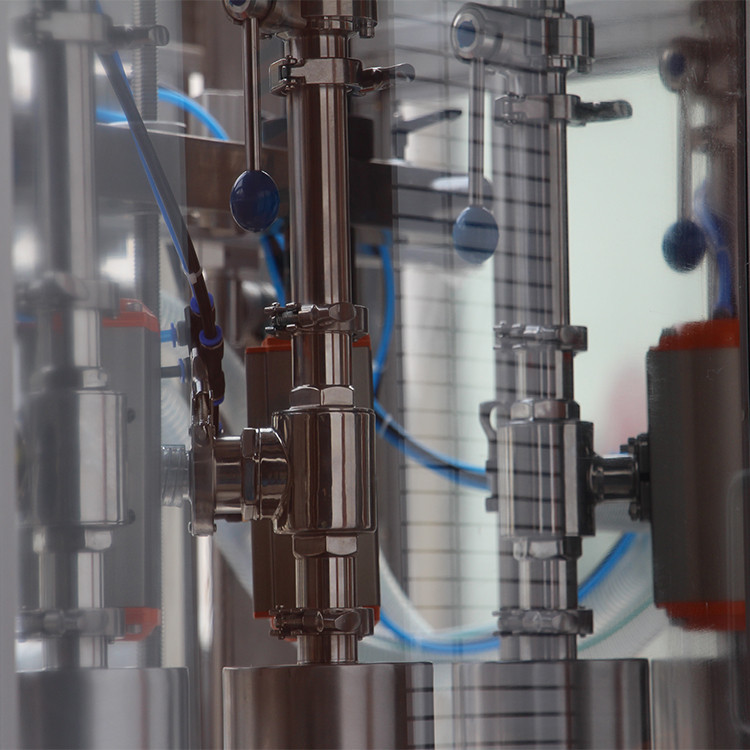

- Filling System

- Clip the bottle neck with steel starwheel. There is no need to adjust the equipment height when changing the bottle shape whose diameters have no much change.

- Rotating disks all make from stainless steel. Large planar toothed bearings can ensure the stable operation of machine.

- High-precision electronic liquid level filling valve makes fast and slow fillings possible.

- Automatic washing cup can circularly and thoroughly clean the filling valve through CIP cleaning program.

- Integrate filling valve with bottle lifting mechanism. The simplified structure makes cleaning easier and could improve the stability of the machine. Bottleneck is clipped by clippers.

View Video

Advanced design

- 1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

- 1.2 Short filling circle, high production capacity.

- 1.3 Changing filling circle, high production capacity.

- 1.4 User may choose the filling volume and decide the filling heads per own production capacity.

- 1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

- 1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

View Video

Machine Oil Filling Machine Main performance parameters

- 1. Capacity: 50ml -100ml ≤ 6000b/h; 500ml ≤5000b/h; 1000ml≤5000b/h

- 2. Bottle type: round bottle Φ40-100 mm, height 80-280 mm flat bottle (40-100mm)*(40-100mm)*(80-280mm)(L x W x H)

- 3. Diameter of bottle opening: ≥φ25mm

- 4. Filling range: 50-1000ml

- 5. Precision:(1000ml)±0.1%

- 6. Air pressure: 0.6~0.8 MPA

- 7. Power source: ~380V,50HZ

- 8. Production line height: 900mm±50mm

- 9. Filling materials: liquid soap, cleaners and low viscous liquid packing

- 10. Bottle feeding direction: From left to right