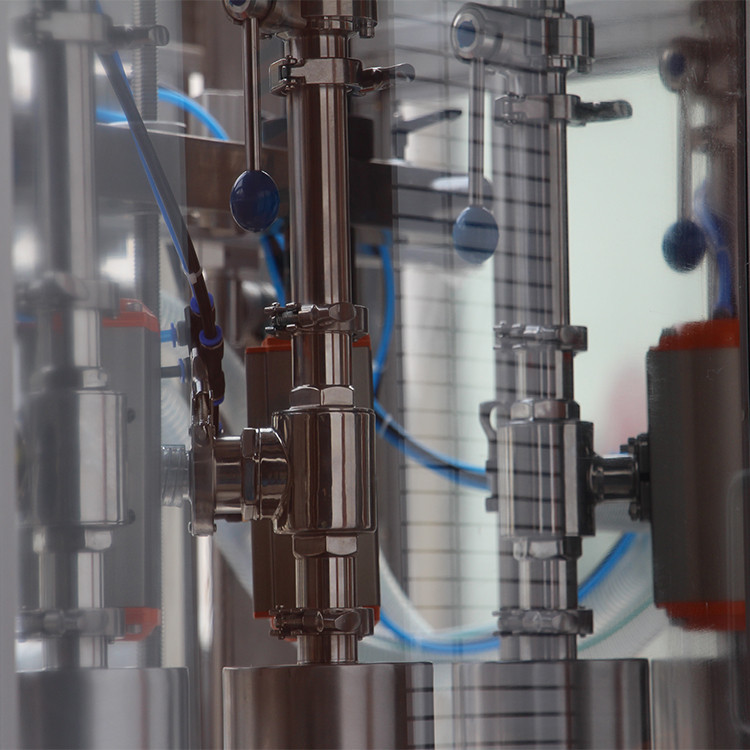

Gravity Chemical Bottle Filling Machine

- The Automatic Gravity Filler is ideal for filling thin liquids with consistent viscosity. Volumetric time gravity filling method produces repeatable and accurate fill volumes. The Gravity Filler is manufactured with a heavy duty 304 stainless steel, tig-welded tube frame and reservoir. It also features user friendly PLC controls and touch screen HMI panel. This filler is capable of accommodating up to 16 heads, and utilizes an automatic product level sensing float system for filling efficiency. Many more features and options are available for even more versatility and customization. Gravity Fillers are utilized by the food and beverage, cleaning and specialty chemical, pharmaceutical, cosmetic and personal care industries for various filling projects. The Automatic Gravity Filler can be built to suit a wide variety of applications including sanitary, hazardous, flammable, and corrosive products and environments.

Gravity chemical bottle filling machine Introduction

- All the machine material are constructed by PVC to anti corrosive including the conveyor, control box.

- Schneider PLC control, and Schneider touch screen operation it is easy for changing size or modifying parameters.

- Pneumatic elements are all imported, stability and reliability.

- Photo-electric sensing and pneumatic linking control, automatic protection for shortage of bottle.

- Close positioning design, easy governing, suitable for packing of all sizes of bottles.

Gravity chemical bottle filling machine Features

- 1. Only need three people (one operator, two assistants) to operate this production line.

- 2.Fast and efficient unscrambler is suitable for flat and round bottles and easy to adjust for size. Fallen bottles will be returned to the elevator and the unscrambler will alert operator to unfilled bottles.

- 3. Servo volumetric filling machine is highly precise. Filling nozzles automatically adjusts to different bottles and reduce foam.

- 4. The rotary capping machine is 100% qualified and rejects dented or broken caps.

- 5. The automatic carton opening and sealing machines are easy to operate and speed up production.

Advantage of Gravity chemical bottle filling machine

- Our bottling equipment features robust construction from HDPE, UHMW, and PVC construction which holds up to corrosive environments.

- Easy cleaning VKPAK’s filling machines are design and constructed to allow for a “quick flush” which maximizes their cleaning efficiency.

- Flexibility, versatility and simplicity are key components of each of the filling systems we design. This allows many products and containers can be run on one machine with tool-less changeover. By choosing the right filling methods, a large variety of products can be filled.

- All of our bottling equipment is customized for your specific application. The tank capacity, number of fill heads, contact parts, and frame dimensions are all customizable for your particular needs.E-PAK filling machines are simple, easy to use, and feature quick setup & change over. Operators can store fill times as “recipes” for quick setup.

- From Entry-level table top systems to fully automated end to end corrosive filling systems, our experts oversee every step of design, manufacturing and installation of your bottling equipment.

Gravity chemical bottle filling machine Features & Benefits

- Versatile design

- Capacity to fill 1/4 ounce up to 5 gallon containers

- Robust construction

- Stainless steel and anodized aluminum construction protect these machines for longer life.

- HDPE, UHMW, and PVC also available for corrosive products

- Microprocessor controls with program storage

- Changeover is quick with the ability to store multiple programs in the PLC controller. Filling and container indexing settings are easily

- programmed and saved with our automatic setup mode, enabling changes to be made quickly and effortlessl

- Tool-less adjustments

- Reduce downtime with simple changeover adjustment features

- Customized per application

- Construction materials, contact parts, number of fill heads and other

- options are fitted to meet each specific application

- Flexible

- Modularity and simplicity are intrinsic to the design. Versatile machine

- options and a wide range of programmability make this filler flexible

Advanced design

- 1.1 The machine suits for the filling of different sizes of vessel may change the filling sizes within a few minutes.

- 1.2 Short filling circle, high production capacity.

- 1.3 Changing filling circle, high production capacity.

- 1.4 User may choose the filling volume and decide the filling heads per own production capacity.

- 1.5 The touching operation color screen, can display the production state, operation procedures and filling ways, tableau objective, operation simple and maintenance convenient.

- 1.6 Each filling-head is equipped with a bottle-mouth-clamping device, ensuring the injecting material correct aiming at.

Parameter

| VK-GF Full automatic gravity chemical bottle filling machine | ||||||

| Filling Volume | 100ml-1000ml 250ml-2500ml 500ml-3000ml 500ml-5000ml | |||||

| Filling Material | Shampoo,Lotion,Cooking oil,Lube oil, Degergent liquid,Hair oil, Honey, Sauce,and so on | |||||

| Filling nozzle | 2 | 4 | 6 | 8 | 10 | 12 |

| Capacity(B/H) | 800-1000 | 1500-1800 | 1800-2500 | 2500-3000 | 3000-3600 | 3600-4200 |

| Filling Precision | Less Than 0.5% | |||||

| Power supply | 220V Single phase 50HZ 380V Three phase 50HZ | |||||