Brake Fluid Filling Machine

- Application:mainly used for low to medium viscosity and paste filling in food&beverage, daily chemical,pharmacutcial,pesticides and other special industries,such as oil,water mineral water drinking water,honey,toothpaste and so on.

View Video

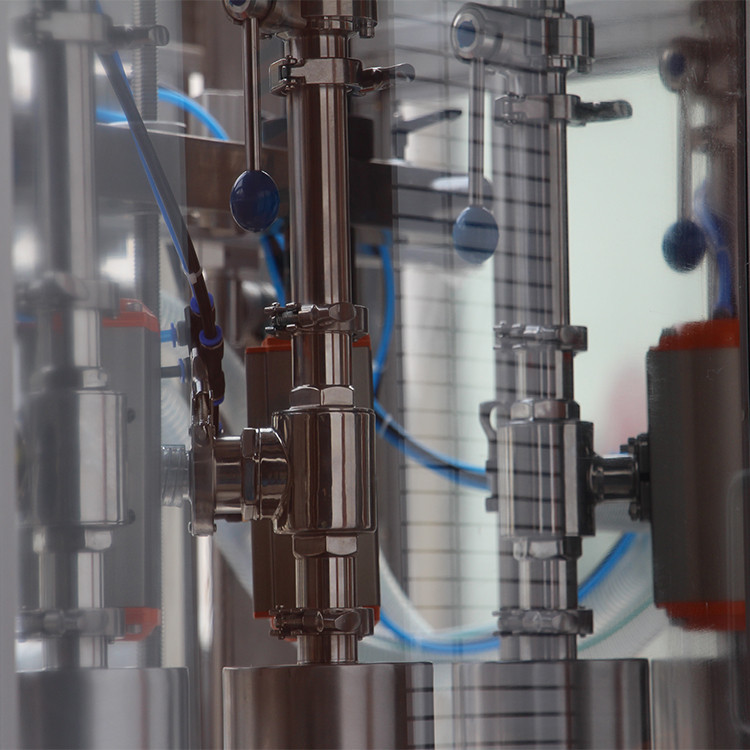

Brake Fluid Filling Machine Introduction

- Brake Fluid is among the many liquid products that VKPAK Machinery packaging equipment can fill and package. Many types of facilities can utilize complete systems of engine coolant filling equipment, cappers, conveyors, and labelers to meet their needs. Our machinery is also capable of filling and packaging many other types of liquids with varying levels of viscosity

View Video

Brake Fluid Filling Machine Features

- 1 Engine Coolant liquid is designed to be compact and reasonable.

- 2 Choosing the international brand of electrical components. The main powered cylinder, chose the Taiwan Airtac double-action cylinder and magnetic switch, the Japanese Mitsubishi PLC computer, photo electricity and Taiwan-manufactured touching screen, ensuring a good quality and lasting steady performance.

- 3 Convenient maintenance without any tools. This machine can be dispart, cleaned and fixed easily.Filling precision and quantity are adjustable and should be regulated among a big range firstly,then be trimmed.

- 4 We can customize the filling machine with specific filling-head number and particular cylinder volume,based on the user’s production demand. 6-head, 8-head and 10-head can be chosen.The cylinder volume can be chosen from 25-250ml, 50-500ml and 100-1000ml. The whole machine is speed-adjustable.

- 5 Considering the different viscosity of user’s material ,we especially set a special filling valve to adjust to different situations. and We also designed a descending filling lift system. In order to make the material-falling accurate at the bottle mouth , we designed a horizontal bottle-aiming fixture device.

- 6 The machine set a weight filling program to fix the flow parameter and makes the machine adjustable to the complicated material varieties. The system can realize the one-machine multi-use without other parts and decrease the equipment’s repeated investment.

View Video

Advantage of Brake Fluid Filling Machine

- .no bottle no filling facility and automatic stop the next work when the bottle was not in the right position

- equiped with high quality drip-proof filling nozzles,after filling,no drops

- heavy duty sus 304 stainless steel, high quality tig welded tube frame and material contacted part is sus 316 stainless steel

- it comes with the PLC standard and Schneider electrical parts(something wrong,they fix it up for free)

- filling nozzle slowly-out filling mode to prevent from foamy

- high consistent liquid fill level because can adjust the whole measurement pump’s filling volume in a lot, and minimum adjustment to each measurement pump,easy to operate and adjustment

- piston quantitative theory

- veriable speed control,can control the filling speed well

- available with 4 to 12 filling nozzles

- servo motor driver,low maintenance,can work more hours compared with normal motor

- cooperation between imported electromagnetic clutch and electromagnetic brake to decrease inertia,so high filling precision of 0.5%

- alarming system in case of abnormal operation

- Max filling volume up to 5 L

- 1 year guarantee period and lifetime maintenance

View Video

Install a Customized Liquid Packaging System in Your Facility

- All of the liquid filling and packaging machinery available from VKPAK Machinery enables customers to fully customize production lines for engine coolant and many other types of liquid products. We can help you decide on the best machinery for your specific application and design a complete configuration of equipment to meet your needs. We can assist with everything from machine selection to installation and setup. With our help, you’ll maximize your facility’s productivity and profitability.

- If you would like to get started on the design and implementation of a complete engine coolant filling machine system, contact VKPAK Machinery today and one of our knowledgeable experts will be able to assist you immediately. We’re ready to help you design a completely customized system of equipment based on your individual needs.

View Video

Implement a Complete System of Brake Fluid Filling Machine

- Brake Fluid is a thicker product that our machinery is capable of handling. In addition to engine coolant filling machinery, we also offer a variety of other types of liquid packaging equipment to complete your packaging systems, reducing the risk of breakdowns while simultaneously increasing productivity. We offer many different customization options to meet your application’s specific needs.

- After the filling process finishes, capping equipment can place custom-sized and -shaped caps on engine coolant bottles that forms and airtight seal that protects the product from leakage and contamination. Labelers can then apply Mylar, paper, or clear plastic labels that display unique branding, text, and images. To keep transportation of products consistently efficient throughout the filling and packaging processes, conveyors are available in custom configurations with varying speed settings. With a complete combination of reliable engine coolant filling machines installed in your facility, you can experience a high level of efficiency that gives you the best results from your production line

View Video

Brake Fluid Filling Machine Parameters

- 1. Capacity: 50ml -100ml ≤ 6000b/h; 500ml ≤5000b/h; 1000ml≤5000b/h

- 2. Bottle type: round bottle Φ40-100 mm, height 80-280 mm flat bottle (40-100mm)*(40-100mm)*(80-280mm)(L x W x H)

- 3. Diameter of bottle opening: ≥φ25mm

- 4. Filling range: 50-1000ml

- 5. Precision: (1000ml)±0.1%

- 6. Air pressure: 0.6~0.8 MPA

- 7. Power source: ~380V,50HZ

- 8. Production line height: 900mm±50mm

- 9. Filling materials: liquid soap, cleaners and low viscous liquid packing

- 10. Bottle feeding direction: From left to right