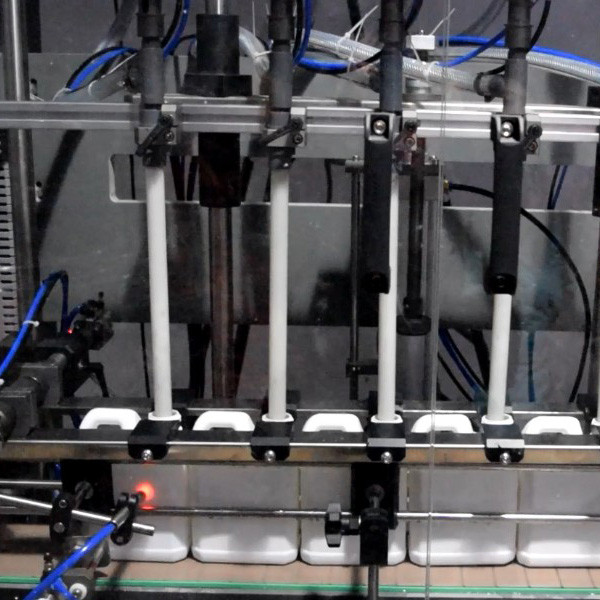

Acid Liquid Filling Machine

- Corrosive liquid filling machine is built from corrosive resistant plastic material and specially designed to use in harsh environments where caustic liquids and gasses cause accelerated deterioration to standard filling machinery.

- Recommended products for this machine Disinfectant, Acid, Bleach, Ammonia, Brine, Salt solution, Caustic liquid, Alcohol, Insect pesticide, Solvent,Alcohol etc.

View Video

Acid Liquid Filling Machine Introduction

- 1. This anti corrosive filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

- 2. Contact liquid parts is use anti corrosive non-metallic material and with diving function ,can effectively eliminate the bubbles.

- 3. The filling machine mainly use for packing of chemical products, such as detergent, bleaching, sulphuric acid, , gel-water, strong acid liquid fertilizer, can suits for packing of all kinds of bottle shape and irregular bottle.

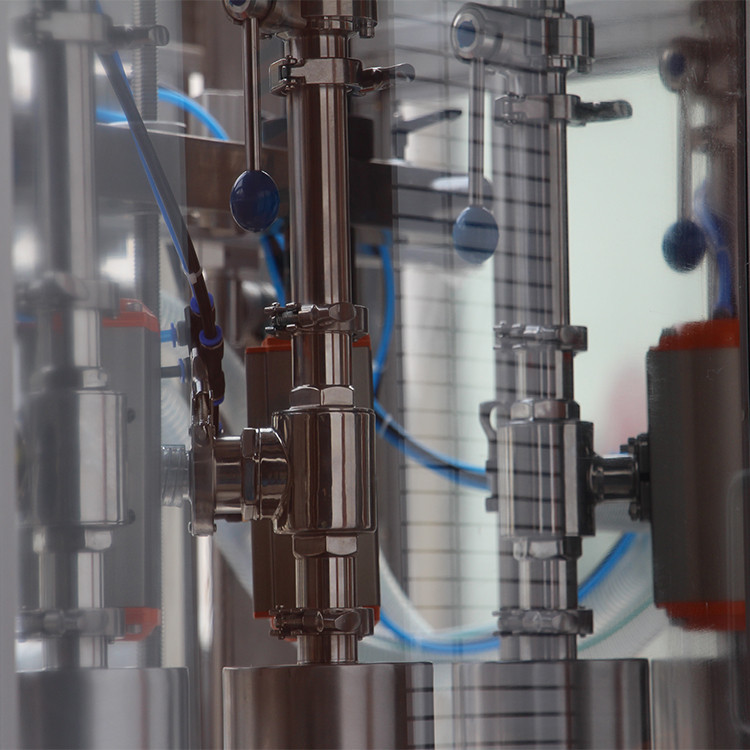

- 4. The diaphragm valve is within the body and cover is equipped with a flexible diaphragm or combination of the diaphragm, the closing member is connected to the diaphragm of a compression device.

- 5. Diaphragm valve has the advantage of its operating mechanism pathway is separated with the media, not only to ensure the working medium of pure, but also prevent pipeline medium impact operating mechanism in the possibility of working parts.

View Video

Acid Liquid Filling Machine Features

- Controlled by Schneider servo system.

- Adjustable filling speed

- Accurate to ±0.1% (1000ml)

- Integrated digital control with Schneider PLC and high-tech touch screen controls for easy operation.

- Designed for easy changeover and cleaning.

- Professional manufacturing techniques using the ISO-9001 system.

- GMP standard stainless steel.

- Bottom-up filling for option.

- Bottle neck location.

- No bottle-no fill system.

- Filling zone protected by stainless steel frame

- Volume is easily adjusted through touch screen. Filling pistons are controlled by servo system.

- Individual piston adjustment.

- Digital control system to enable multiple filling actions on the same bottle for double, triple and more.Nozzles can set to be above bottle mouth or bottom up, synchronizing with liquid level (beneath or above) to eliminate bubbling of foamy liquids.

- Three-step-filling, it can fill slowly at the beginning and then accelerate to faster speed, finally slow down once again to finish up. This can prevent foamy liquids from bubbling and avoid spillage.

View Video

Advantage of Acid Liquid Filling Machine

- Use strong and long life PVC material

- PLC control, and adjust the filling volume by touch screen

- Low cost for investment

- Diving filling head to anti foamy

View Video

Acids & Corrosive Bottling Equipment Applications

- Water-thin and foaming corrosive liquids

- Medium viscosity corrosive liquids

- Acids such as hydrochloric acid

- Bases such as sodium hypochlorite

- Pool chemicals

- Cleaning products

View Video

Standard Filling Machines

- HDPE (high density polyethylene filling systems frame construction

HDPE reservoir with poly float system

Kynar or Teflon fill valves

Braided PVC tubing and polypropylene fittings

Touch-screen operator interface

Tabletop, semi-automatic and fully automatic filling machines - available

Optional enclosures for ventilation and safety can be fabricated out of HDPE - Conveyors

HDPE and PVC construction, stainless steel hardware

Corrosive resistant HDPE belting

Variable speed motor

HDPE rail system with tool-less adjustments

Adjustable height - Turntables

HDPE construction

Variable speed motor

Clockwise or counter clockwise rotation

HDPE rail system with tool-less adjustments

Adjustable height

View Video

Specification

| Model | VK-FF Acid Liquid Filling Machine | |||||

| Nozzles | 6 | 8 | 10 | 12 | 16 | 20 |

| Idea Filling range | 100-1000ml, 500-5000ml | |||||

| Application bottles | Round , flat or regulars bottles | |||||

| Capacity Per 1000ml | 24b/m | 32b/m | 40b/m | 48b/m | 64b/m | 80b/m |

| Power supply | 220V,50hz | |||||