Automatic Linear Trigger Capping Machine

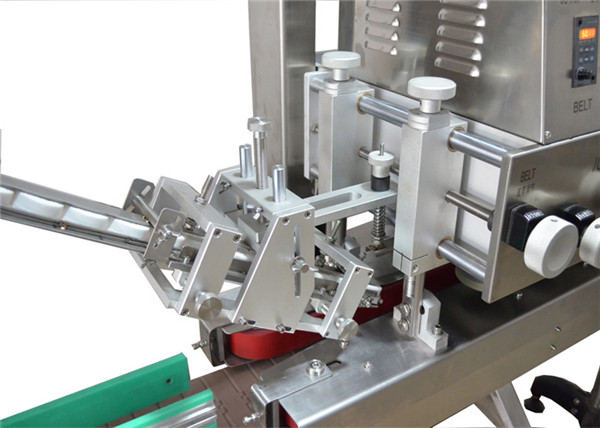

- Automatic capping machine is flexible, durable and works with most containers and caps includingflat caps, sport caps, metal lids and many others.The machine has practicability in field of pharmaceutical, pesticide, chemical, foodstuff etc. It is real ideal equipment for bottle screw capping, also applied to seal aluminum cap, the ft proof cap, screw-thread cap, ROPP cap etc. It’s built on a heavy duty, tig welded, stainless steel frame with anodized aluminum plate construction to provide durability in almost any packaging environment. The modular design lets you start with just a cap tightener and easily add capabilities when you need them.

View Video

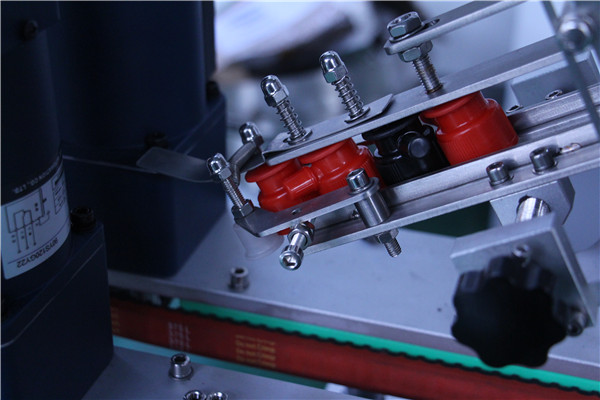

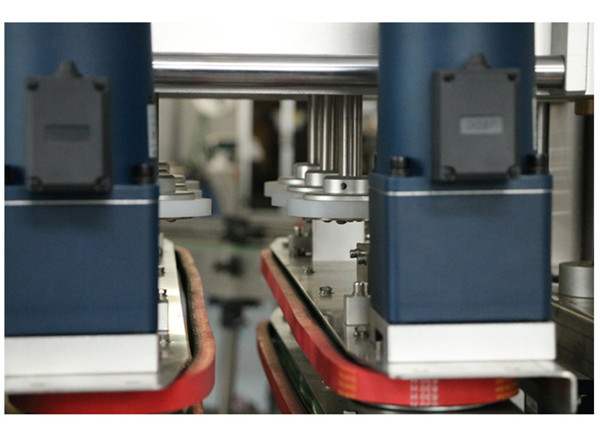

6 Wheels Linear Trigger Capping Machine Introduction

- Inline Capping machine Depending on customer output needs, It specially designed for the tightening of pre-threaded caps and consists of a linear capping unit, stainless Steel slat conveyor and gripping belt assembly, The filled bottle coming with cap chute and pick up cap with the cap comes on an in-feed conveyor where the cap is tightened by three/ four roller wheel pairs of rollers while it is being held by the gripping belt. The speed of the slat conveyor and bottle gripping belt is synchronized and can be varied by AC variable inverter drive. The inline capper machine can be provided with the Cap elevator , rotary / vibratory feeding system for automatic cap dispensing , this systems fixed by our production team as per cap and bottle designed.

- With good conveying ability, lift elevator is designed to elevate different types of caps with different specifications. The elevator is suitable to automatically convey plastic and metal bottle caps into the caps collection device of capper main machine.

The conveying chain adopts high strength wearproof plate chain, lengthening the service life of chains and hopper. The high elevate height, slow stable conveying speed and advanced design, ensure the stability of the whole machine. Easy operation and maintenance with little consumerable spare parts. - Elevating speed is about:1.25m/s.

- Inline capper / linear screw capping machine best suitable for Detergents, Oils , Liquid soaps , Household/janitorial cleaners , Glue/Adhesives ,Household cleansers , Herbicides , Polishes , Lube oil, edible oil, Pesticide , cosmetic bottle glass jar or bottle, Jerry can, lubricant can, HDPE jar or bottle, PET jar or bottle Inline / Linear belt gripper type capping machine suitable for Pharmaceuticals, Dairy, Breweries, Edible Oil, Food, Distilleries, pesticides, Toiletries, Cosmetics, Lube, Ancillaries etc.

View Video

6 Wheels Linear Trigger Capping Machine Feature

- Simple structure and easy operation.

- 304 stainless steel material thus easy maintain and cleaning.

- Hopper (Volume at about 150L) is capable to store numbers of caps.

- Constant elevating speed and stepless adjustment.

- AC 220V motor drive, good generality.

View Video

Main technical parameter

Model | automatic spindle Bottle Capper Machine |

Capacity | 50-200bottle/min (subject to bottles and cap) |

Cap diameter | 20-120mm |

Bottle Height | 40-460mm |

Cap type | Plastic cap |

Power | 1600W |

Weight | 500Kg |

Dimension | 1060mm*900mm*1600mm |

Cap feeder | 1 Elevator Feeder,2 Vibrator Feeder |

View Video

Application

- Will work with most containers and caps including flat caps, sport caps, continuous thread metal lids and many others

- Laundry Soap Cap

- Sports Cap

- Salsa Capping

- Machine Capping

- Machine For Liquids

- Viscous Liquid

- Capping Machine

- Capping Machines For Flammable Liquids